Automatic Pallet Changers for Machining Centers Which Do Not Move in Y Axis.

Pallet sizes range from 30" x 16" (762mm x 406.4mm) up to 150" x 50" (3810mm x 1270mm) with up to 8000 lb (3632 kg) weight capacity (weight must be evenly distributed on pallet).

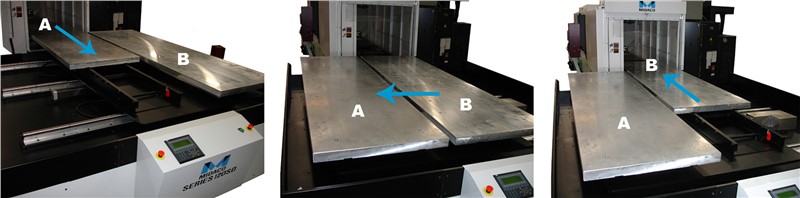

When pallet "A" comes out of the machine, the shuttle shifts pallet "A" along the Y-axis and moves "B" into position. The shuttle then sends pallet "B" into the machine. This operation is reversed for the next pallet change.

Light Curtain

All models of the Y-Axis Shift Automatic Pallet Changer System are available with a Light Curtain package. With 3-sided guarding via a light emitter, mirrors and sensors, a pallet change will not occur if the invisible light beams surrounding the shuttle system are breached.

Benefits of MIDACO’s Y-Axis Shift Auto Pallet Changer include:

- Heavy/Large workpieces easily loaded outside the machine

- Increased operator, machine, and overall center productivity

- Reduce set-up time on repeat jobs by dedicating tooling onto pallets

- Minimized spindle downtime for continuous operation levels

- Improved process and cost efficiency for your machining center