Don’t overlook chip and coolant handling in your automated machining process

When automating CNC machining, chip and coolant management

are often overlooked—but they play a critical role in maintaining efficiency,

precision, and machine longevity. Without proper handling, accumulated chips

and contaminated coolant can lead to tool wear, poor surface finish, safety

hazards, and costly downtime. MIDACO provides advanced chip and fluid

maintenance solutions to keep your CNC operations running smoothly with minimal

intervention.

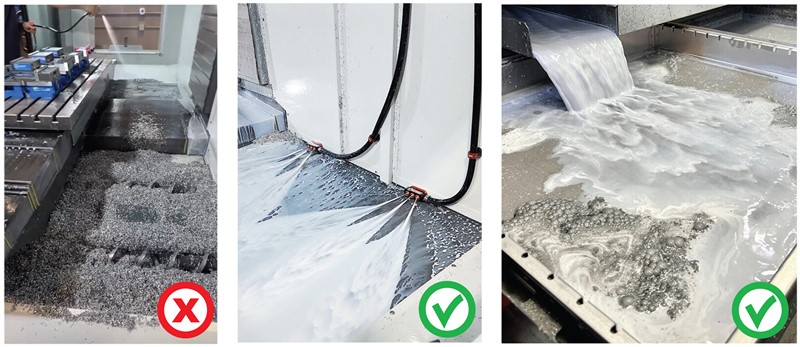

CNC Chip Fan

CNC Chip Washdown System

Automatic Coolant Cleaning System

Industrial Vacuums for CNC

An Industrial Vacuum for CNC machine cleaning maintenance provides an efficient and reliable solution for removing chips, dust, and excess fluids from the work area, ensuring a clean and safe environment. With advanced filtration, it effectively separates CNC chips from coolant, preventing contamination and extending the life of both the machine and the coolant. This helps reduce downtime, minimize manual cleaning efforts, and prevent damage to critical components such as guideways and spindles. Some industrial vacuums also offer fluid reintegration, allowing filtered coolant or oil to be returned to the system, reducing waste and lowering operating costs. By improving cleanliness, enhancing coolant efficiency, and extending equipment life, an industrial vacuum is a valuable tool for maintaining peak CNC performance.