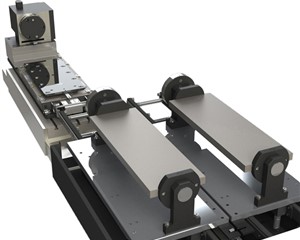

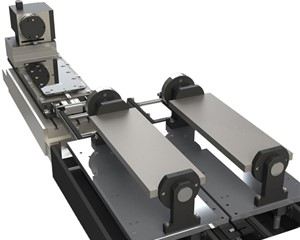

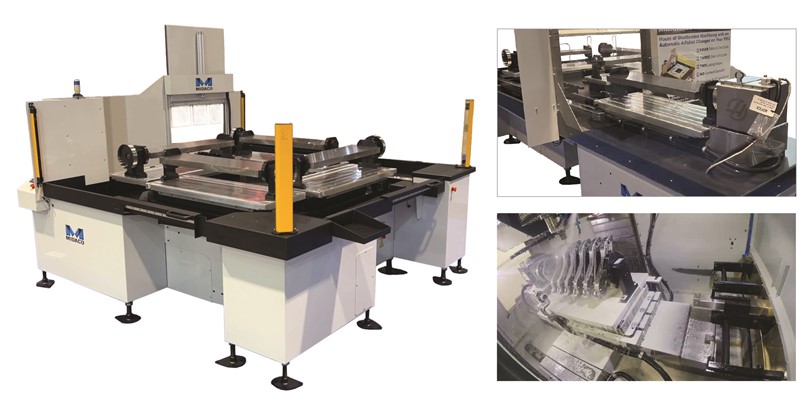

Midaco Trunnion System for 4th Axis Machining

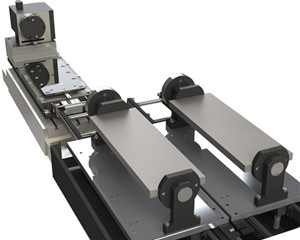

ONLY ONE 4th Axis is required to get the benefits of a Horizontal Machining Center on your VMC equipped with a MIDACO Automatic Pallet Changer. Increase 4th Axis productivity by adding our TRUNNION SYSTEM.

If you’re looking for new ways to innovate on your machining floor, perhaps you aren’t actualizing the full potential of your machining center at hand.

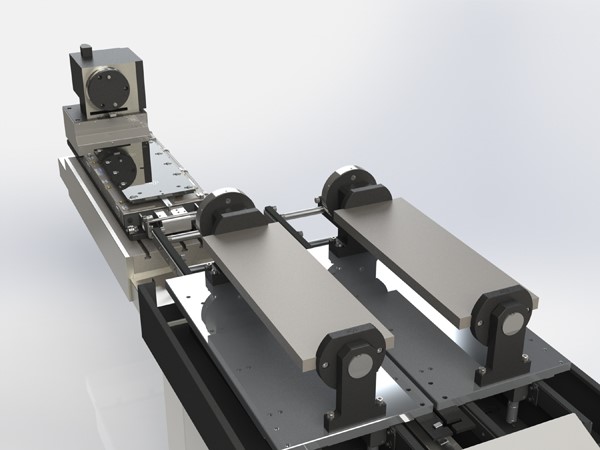

NO Cable Management Required

This system includes one 4th axis actuator assembly and two trunnions which are then mounted on your new or existing Automatic Pallet Changer, and it works with any 4th axis rotary-indexer (not included). Additional individual trunnions are also available separately.

Only ONE Rotary Indexer Needed for Two Pallets

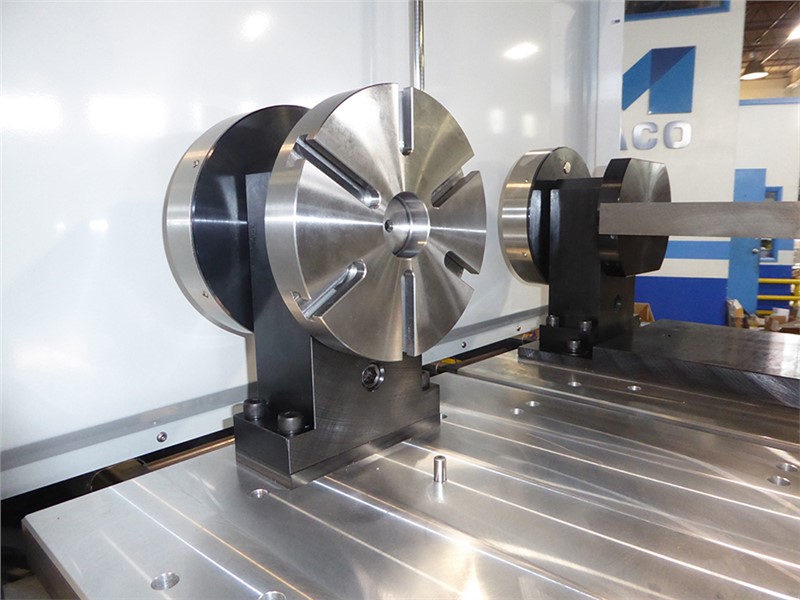

Once transferred into the machine table, the pallet clamps onto the MIDACO receiver and the trunnion automatically engages with the 4th axis rotary indexer, providing a cost-effective solution to increase your VMC’s capability by machining 360 degrees without needing cumbersome cable management.

Vertical Rotary Faceplate

For pallet sizes from 22" x 15" up to 50" x 24"

With MIDACO’s state-of-the-art automation, paired with its variety of Trunnion Systems, unlock the unlimited potential of your machining centers while increasing efficiency and output at the same time.

At MIDACO, our guarantee is that we consistently strive for quality and excellence in product design, manufacturing and service to our worldwide customers and have cemented ourselves as leaders in the industry due to our premier products and unmatched customer service.

For more information

Call or complete our online contact form today.