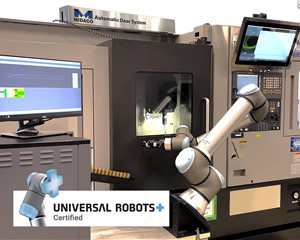

MIDACO’s AutoDoor Opener is Universal Robots+ Certified for Collaborative Automation and CNC Machine Tending

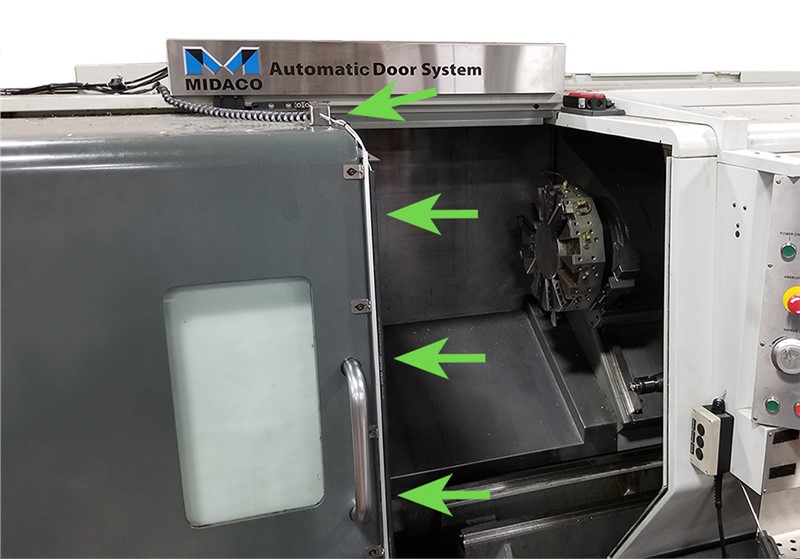

AutoDoor Openers are built specifically for your CNC and include mounting hardware and the UR Cap to simplify the interfacing task. Your UR Cobot will command the open/close of the CNC door for loading parts. Door will automatically reverse if met with any resistance or an obstruction during closing. Add a MIDACO AutoDoor Opener to your machining process and increase productivity with UR collaborative automation solutions.

Sizes starting at 18"-24" Single Door Opener up to 126" Double Door Opener

- Automatically opens and closes the machine door

- Helps reduce wear on Cobot

- UR Cap included

- Can be operated manually with included push button pendant

- Safety sensor reverses door automatically if met with obstruction

- “Open Door” command is ignored if spindle is running

- Machine door opening ranging from 18” up to 126"

How Does It Work?

The AutoDoor System comes with its own controller as well as I/O to the UR Controller. After setting up the I/O assignments in the Midaco URCap the robot will be able to command the CNC door open or closed and automatically wait for confirmation that the movement was complete.

Safety Sensor

A safety sensing edge is installed on the machine door in order to stop and reverse the door if an obstruction is detected. The sensing edge signal is also sent to the UR controller to stop the program until the obstruction can be cleared.

Upgrade your unattended machining process with MIDACO AutoDoor Systems. Automatically open and close doors on your CNC milling and turning centers, allowing access for your UR Cobot. Increase productivity and efficiency with MIDACO and UR collaborative automation solutions.