In additon to Pallet Changers for small and mid-size VMCs, in recent years MIDACO has expanded our line of pallet changers to accommodate the need for large precision parts machined to tight tolerances for the aerospace, energy, automotive, medical, military, power generation, oil and gas industries. These jobs cause significant spindle downtime due to the long and involved process of heavy, large part change over. When combined with crane loading, first article inspection and job interruption tasks, the machining center can be idle for 30 minutes... an hour... two hours? Your large Vertical Bridge Mill can be idle up to 70% of the time.

Estimate how a Pallet Changer will eliminate unnecessary spindle downtime and rescue lost profit with MIDACO's ROI Payback Calculator.

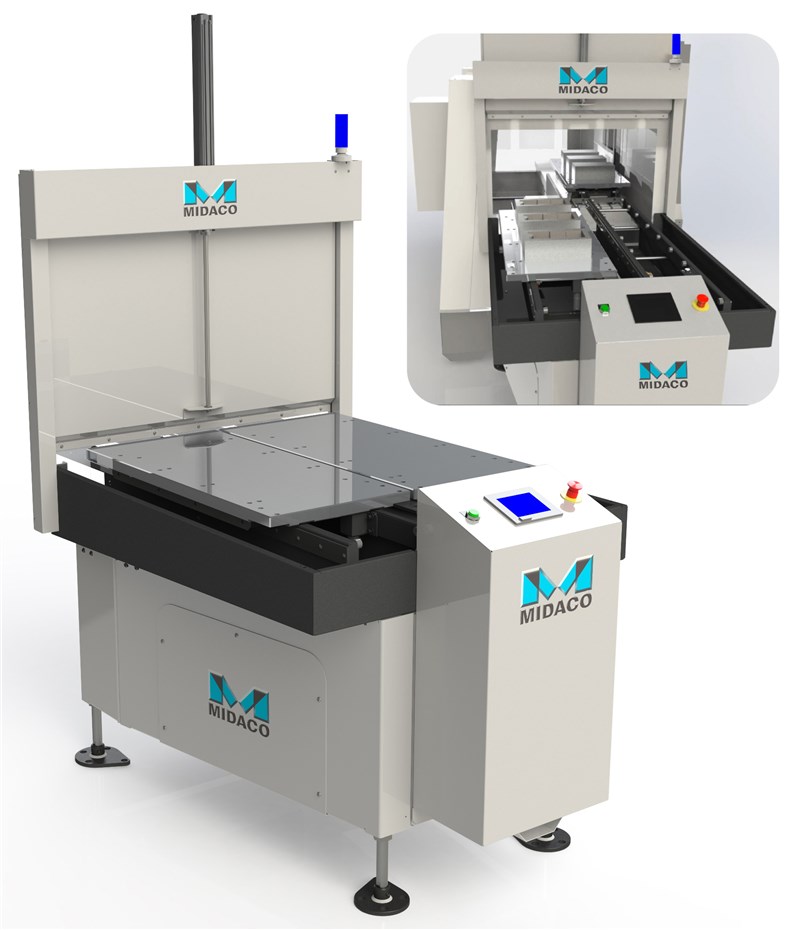

Automatic Large Capacity Pallet Changers:

- Single Shuttle Systems mounted on the right or left side of a VMC with 2 pallets up to 150” x 31” (3,810mm x 787mm) and 8,000 lb (3,632 kg) load capacity receiver (with parts evenly distributed).

- Dual Shuttle Systems (one mounted on each side of the machine) with a total of 4 pallets up to 150” x 31” (3,810mm x 787mm) and 8,000 lb (3,632 kg) load capacity receiver (with parts evenly distributed).

- Single/Dual Shuttle Systems with a total of 2 pallets for machines that do not move in Y-axis, up to 190” x 88” (4,826mm x 2,235mm) pallet size and 32,000 lb (14,528 kg) load capacity receiver (with parts evenly distributed).

MIDACO Pallet Changers at EASTEC 2019:

MIDACO offers a full line of Pallet Changers, AutoDoor Systems & Automation Solutions to fit your Machining Centers

- Manual Pallet Changer System

- Pallet sizes from 12.75"x 10.5" (234mm x 267mm) up to 60" x 25" (1,524mm x 635mm)

- Up to 1,000 lb (454 kg) weight capacity (2,000 lb optional upgrade)

- Automatic Pallet Changer System

- Pallet sizes from 22" x 14" (229mm x 356mm) up to 190" x 88" (4,826mm x 2,235mm)

- Up to 32,000 lb (14,528 kg) weight capacity (with parts evenly distributed).

- Automatic Multi-Pallet Changer System for 5-axis machining

- 19 stations each with a 10" (254mm) dia. round pallet

- Trunnion System for 4th Axis machining

- No Cable Management Needed

- Turn your Vertical into a Horizontal

- Automatic Door System

- For single and double doors

- Operator ergonomic benefits

- Ideal for robot loader applications

Comments