Our dual pallet changers can be retrofitted onto nearly any make, model, and brand of VMC—including both new and existing equipment. By giving your operator twice as many pallets to work on within the same piece of equipment, they effectively double output to significantly increase profits.

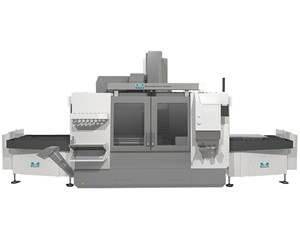

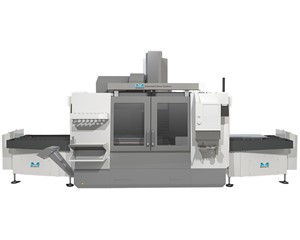

Automatic Dual Pallet Changers for Machining Centers

Similar to a standard aluminum pallet changer with an automatic door system, MIDACO’s dual automatic pallet changers are designed to reduce spindle downtime and increase operator productivity.

With two separate shuttle units (one mounted on each side of your VMC), our dual pallet changers allow for four pallets of parts to be milled automatically and unattended by the machine operator—compared to the two pallets of a standard aluminum pallet changer. While one of the four pallets is being machined, the other three can be unloaded and reloaded for the next operation, doubling the efficiency and operating capacity of a regular auto pallet changer.

Benefits of MIDACO’s automatic dual pallet changers include:

- Compatibility with Nearly Any VMC Brand

- Improved Process and Cost Efficiency with 4-Pallet Capability

- Minimized Spindle Downtime for Consistently High Production Levels

- Increased Operator and Pneumatic Machine Productivity

- Up to 8,000 Pound (3632 kg) capacity

- MIDACO’s Patented “Dual Air Blast” at Each Contact Point

- Easily Paused Job Cycles for JIT Production

- Quick Pallet Exchange with +/- .0001" (.0025 mm) Repeatability

Optional Features for Dual Pallet Changers

MIDACO has been an industry leader in time- and labor-saving manufacturing solutions since 1969. With a dual pallet changer system, you can extend your VMC’s productivity. Available add-ons and accessories include:

- Light Curtain: three-sided shuttle guarding via a light emitter, mirrors and sensor.

- Custom Pallets: We can provide Cast Iron or T-Slotted Cast Iron custom pallets to fit your dual pallet changer.

- Extended Warranty: Many of our automatic dual pallet changers come with optional factory extended warranties for 100% parts replacement, software upgrades, and a reduced labor rate.