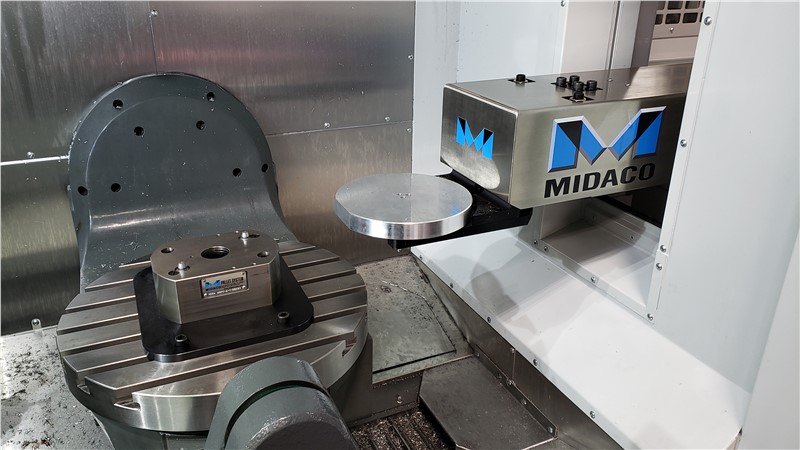

High mix low volume production is not a problem when changing set-ups outside the VMC while it's making chips.

Get 50%-60% More Productivity out of your Existing VMC or 5-Axis

Midaco helps make machining more efficient. This reduces the cost per man hour per piece which helps manufacturers compete with lower cost labor countries.

See what MIDACO customers have to say about their increased productivity.

Your VMC can do MORE with MIDACO

MIDACO offers a full line of Automation Solutions to fit your Machining Centers

- Manual Pallet Changer System

- Pallet sizes from 12.75"x 10.5" (234mm x 267mm) up to 60" x 25" (1,524mm x 635mm)

- Up to 1,000 lb (454 kg) weight capacity (2,000 lb optional upgrade)

- Automatic Pallet Changer System

- Pallet sizes from 22" x 14" (229mm x 356mm) up to 190" x 88" (4,826mm x 2,235mm)

- Up to 32,000 lb (14,528 kg) weight capacity (with parts evenly distributed).

- Automatic Multi-Pallet Changer System for 5-axis machining

- 19 stations each with a 10" (254mm) dia. round pallet

- Trunnion System for 4th Axis machining

- No Cable Management Needed

- Turn your Vertical into a Horizontal

- AutoDoor and Robot Access Door Systems

- For single and double doors

- Operator ergonomic benefits

- Ideal for robot loader applications

- Midaco Fan for CNC

- High-speed automated chip and coolant cleaning fan

- Installed in tool holder and mounted to spindle

- Through coolant ready

- Industrial CNC Vacuums

- Quick CNC clean up saves money in reduced production idle time

- Save on resources appointed to cleaning

- 150 micron PPL filter separates liquids from metal chips

- Increase the lifetime of lubricant with recovery and reintegration

Give us a call at (847) 558-6720 or email us and we would be happy to answer any questions you have about our versatile line of manual and automatic pallet changers and accessories for your machine shop.

Comments