Being woodworking industry experts for over 30 years, Woodpeckers: Precision Woodworking Tools in Strongville OH

understands the value of investing in high quality manufactured tools. Since

its inception in 1988, Woodpeckers has developed its expertise by demonstrating

tools at US woodworking shows. In 1993 they began manufacturing their own

router tables, lifts, fences, mounting plates, measuring and layout tools and a

variety of clamping accessories.

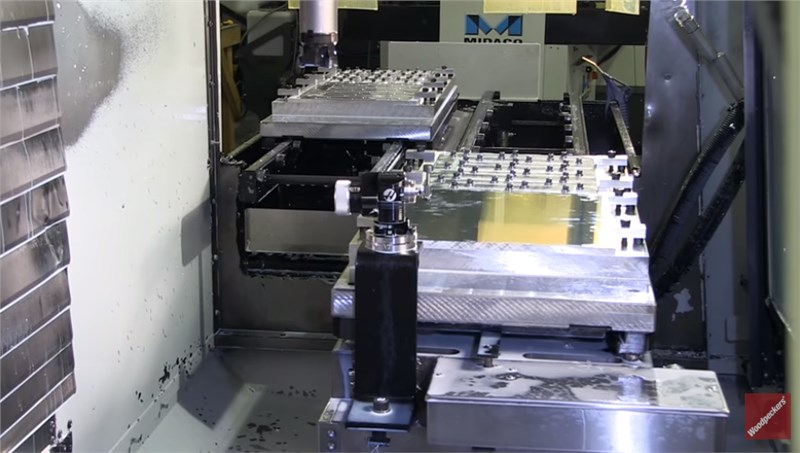

In recent years they have developed a unique OneTIME Tool® program to provide customers with the opportunity to obtain individually machined tools which might otherwise not be available. These tools are offered during a limited time window. Once orders for a specific tool are gathered and the time window closes, Woodpeckers prepares a single production run making enough to fill the orders then retires the product. Like virtually all their tools they are not stamped by the thousands or cast in molds. Each part is machined individually on state-of-the-art CNC equipment at their Ohio facility. Woodpeckers machines, engraves, assembles and packs all their own products and takes pride in the fact that, from start to finish, their tools are truly made in the USA. In order to provide these tools to their customers, they have invested in high performance machines to do the job, such as a VMC paired with a MIDACO Automatic Pallet Changer.

How is it cost effective to run individually machined parts in smaller batches?

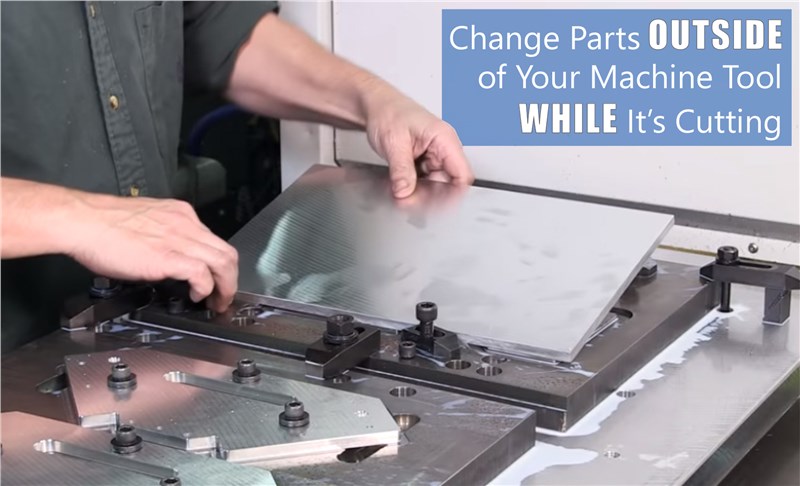

Simple answer… TIME! Time

is not wasted on part change over and the VMC is not sitting idle. Having a MIDACO

Pallet Changer system paired with the VMC allows the operator to load the next batch

of parts outside of the machining center WHILE it's cutting. Once the aluminum or stainless steel pieces are mounted onto the pallet, the operator can attend to other tasks or load another machine while the automated program takes over.

Simple answer… TIME! Time

is not wasted on part change over and the VMC is not sitting idle. Having a MIDACO

Pallet Changer system paired with the VMC allows the operator to load the next batch

of parts outside of the machining center WHILE it's cutting. Once the aluminum or stainless steel pieces are mounted onto the pallet, the operator can attend to other tasks or load another machine while the automated program takes over.

“Prior to these pallet changers our typical spindle utilization was approximately 60%. Afterward, it's typically in excess of 90%.” - R. Hummel, President - Woodpeckers

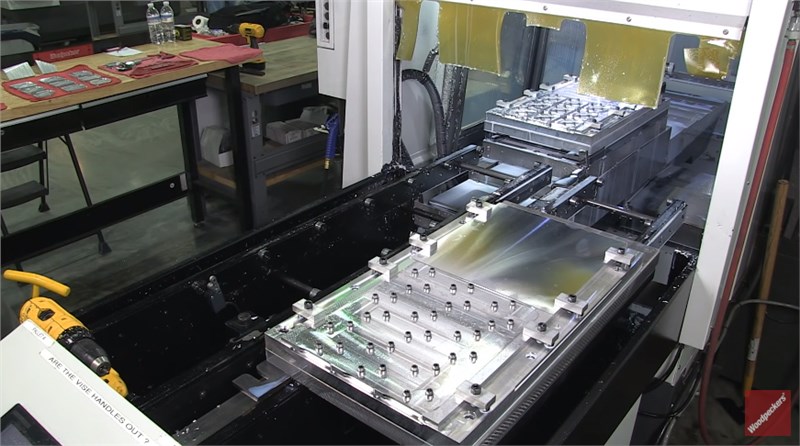

MIDACO's Automatic Pallet Changer is integrated with the VMC control via M-Codes and automatically

feeds the next batch onto the machine table in seconds. Automating the part

change-over decreases machine idle time and increases its spindle utilization.

As a result, projects are completed faster saving time and ultimately saving

money. At a conservative shop rate of $75.00 per hour even a minimal 20 minutes per hour down time during an 8 hour shift can add up to over $52,000.00 of lost profit per year (over $4,300.00 per month), per each machine owned.

MIDACO's Automatic Pallet Changer is integrated with the VMC control via M-Codes and automatically

feeds the next batch onto the machine table in seconds. Automating the part

change-over decreases machine idle time and increases its spindle utilization.

As a result, projects are completed faster saving time and ultimately saving

money. At a conservative shop rate of $75.00 per hour even a minimal 20 minutes per hour down time during an 8 hour shift can add up to over $52,000.00 of lost profit per year (over $4,300.00 per month), per each machine owned.

“…our calculated hourly cost for the Pallet Changer, about $5.50. Dirt cheap for 50% more parts per hour.” - R. Hummel, President - Woodpeckers

Estimate how a pallet changer will eliminate unnecessary spindle downtime and rescue lost profit with MIDACO's ROI Payback Calculator.

Adding MIDACO Pallet Changers to their Vertical Machining Centers has been an asset for Woodpeckers in their production of exceptionally machined woodworking tools. The proof is in the time and money they've SAVED.

For more info on MIDACO Pallet Changer Systems and other productivity solutions, such as AutoDoor Systems and Trunnion Systems for 4th axis machining on a VMC without cable management, visit www.midaco-corp.com or contact midaco@midaco-corp.com (847) 558-6270.

Comments