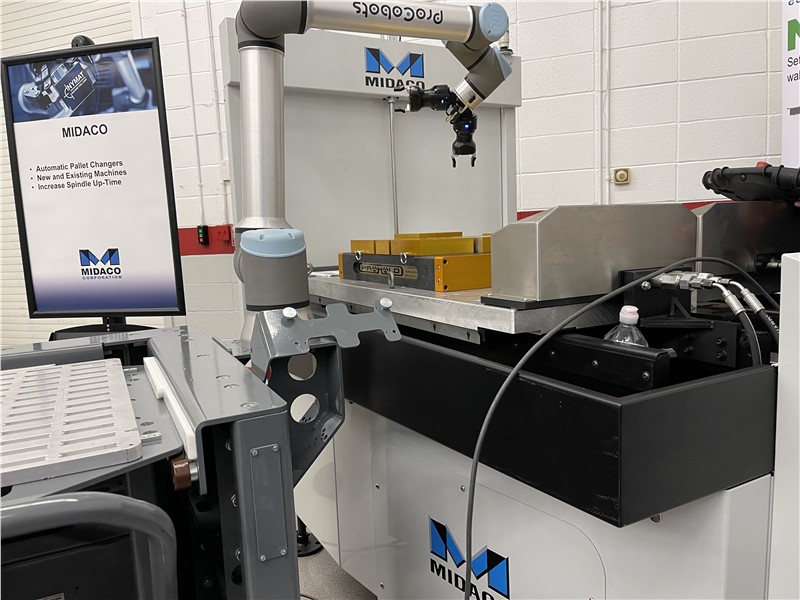

Hydraulic Docking System for Automated Fixture and Vise Clamping on Automatic Pallet Changers

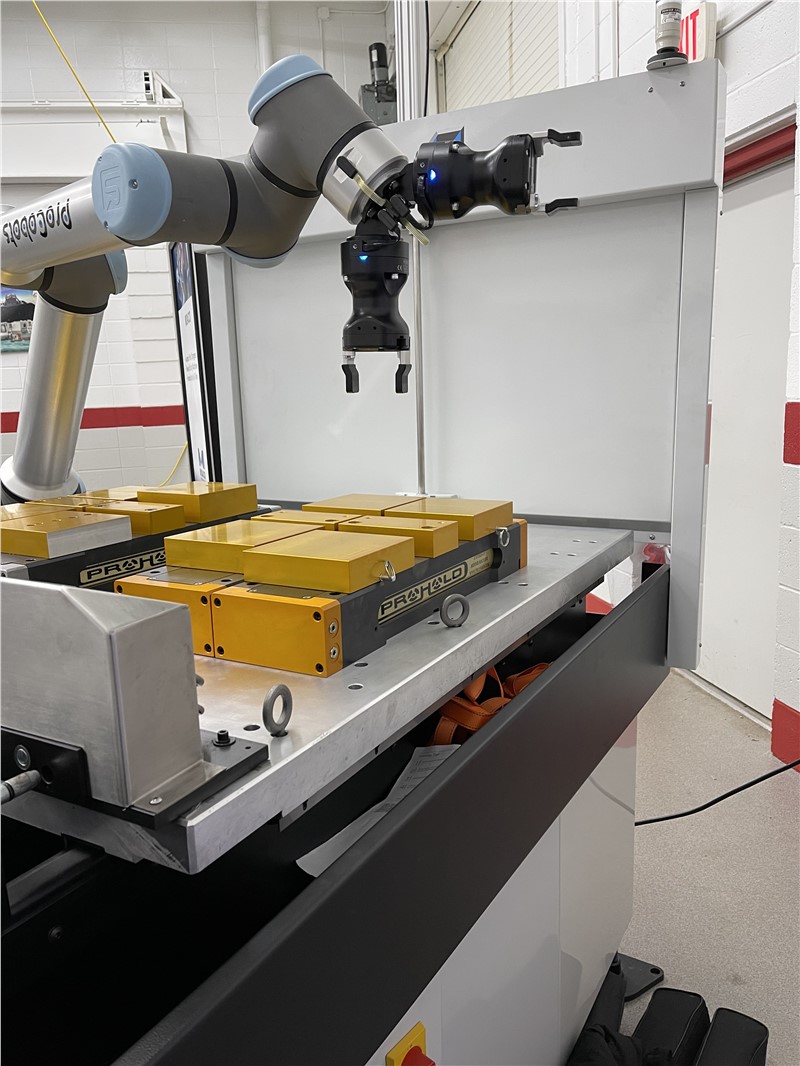

An ideal workholding solution for unattended robot/cobot applications.

Enhance your productivity even further with MIDACO's Robot Arm Mount available for A30SD & A40SD, AS50SD & A80SD Automatic Pallet Changers.

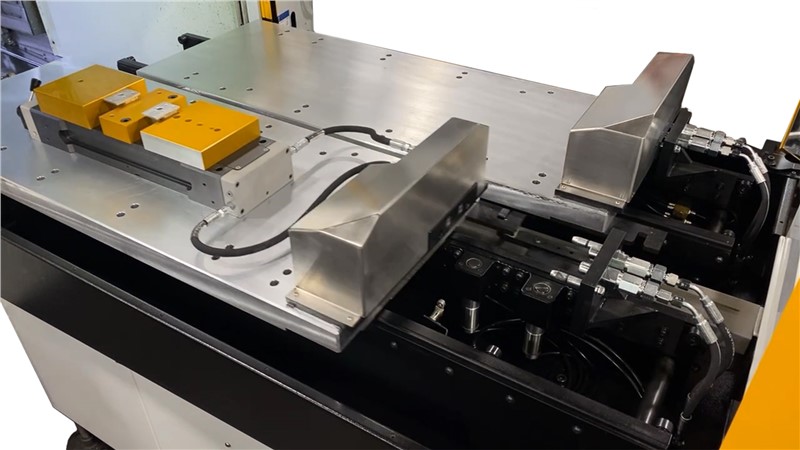

When new parts are put onto the pallet, the Hydraulic Docking System locks fixtures or vises into place and the pallet enters the machining center without the need for hose management.

When new parts are put onto the pallet, the Hydraulic Docking System locks fixtures or vises into place and the pallet enters the machining center without the need for hose management.

Clamping fixtures or vises will STAY CHARGED on the pallet WITHOUT HOSES while in the machining center.

No Hose Management Required

When a pallet comes out of the machining center, it locks back into the Hydraulic Docking Station and automatically releases fixtures or vises allowing parts to be quickly replaced.

Features:

- Hydraulic clamping WITHOUT HOSES

- Hydraulic power unit provides 3000 PSI at 1 GPM

- 2HP 230/460 3-PH motor

- 3 ports in, 3 ports out

- Quick disconnect system

- Automated clamping through the Pallet Changer control panel

Note: fixtures and vises not included. This Hydraulic Docking System is an accessory for single shuttle Automatic Pallet Changers. Configuration at an additional cost may be required for Automatic Pallet Changers with “Dual” Shuttles.