"Robot Ready" Automatic Pallet Changer

Need an extra hand?

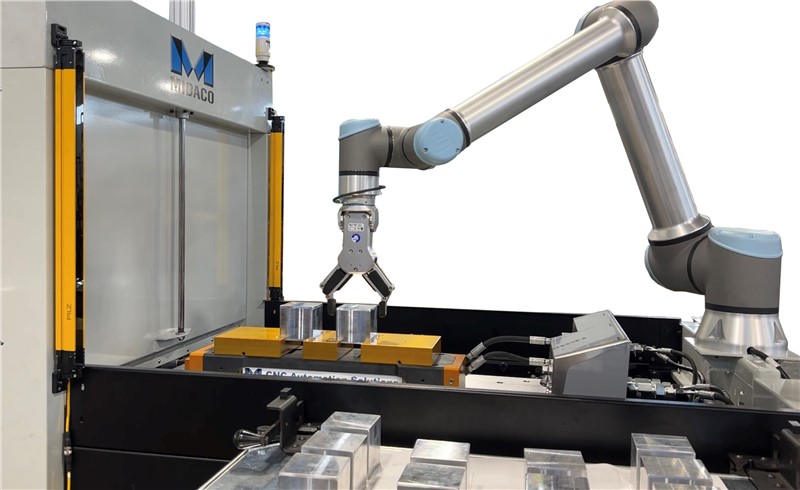

MIDACO's A16SD, A30SD, A40SD, AS50SD, A50SD & A60SD series Automatic Pallet Changers can be modified to mount a robot/cobot directly on the pallet changer control panel for enhanced collaborative automation. Let the robot/cobot set-up parts on the pallet changer outside of your VMC while the spindle is cutting, freeing the operator to perform other tasks.

Pallet sizes for XY travel from 22"x15" up to 64"x32"

Eliminate the need for your VMC to sit idle while your robot/cobot loads parts directly onto the machine table.

Reduce strain by automating repetitive part loading tasks. A robot/cobot mounted on the shuttle can easily access parts on a table or conveyor set up along-side of your MIDACO Automatic Pallet Changer and do the loading for you with precision and reliability.

MIDACO requires robot/cobot arm specifications prior to this customized Automatic Pallet Changer order.

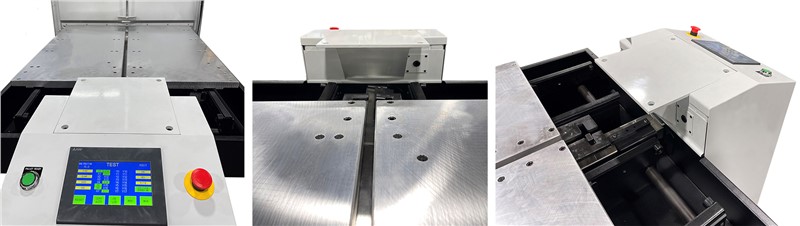

Once robot/cobot specifications are confirmed, the shuttle's front control panel is modified with a platform base ready for easy mounting.

Enhance Your Robot/Cobot Productivity Even Further with a Hydraulic Docking System

With the Hydraulic Docking System, fixtures and vises are automatically clamped and unclamped on the pallet and stay charged inside the machining center WITHOUT NEEDING HOSES.

For more information