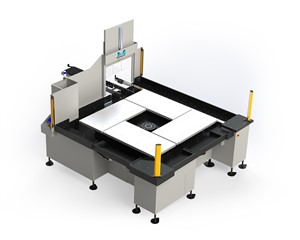

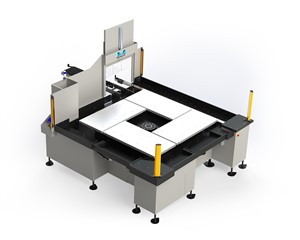

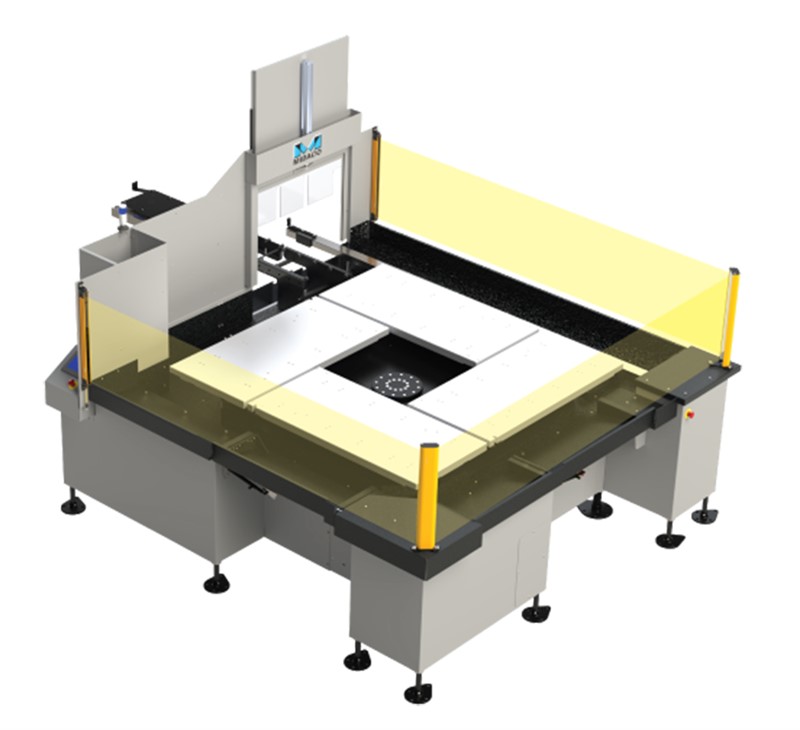

Automatic CE 4-Pallet Pool

For international export outside of the continental USA

Whether running high volume production of the same part or programming several different set-ups, MIDACO's Automatic 4-Pallet Pool will extend operator walk-away time and maximize productivity on your new or existing vertical mill with 4 pallets on 1 shuttle. Save money by increasing spindle utilization during the machining process and quote more competitively. See Brochure PDF

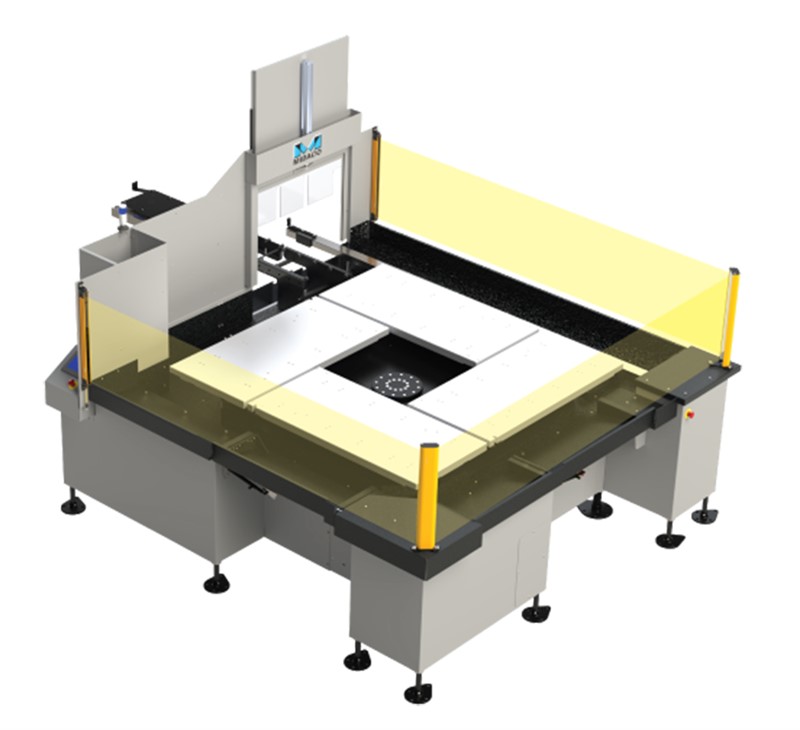

Note: main image and videos show a legacy guard panel design with 2-sided light curtain. Newer models are manufactured with 3-sided light curtain guarding and without panel.

ONE Shuttle + FOUR Pallets = QUADRUPLE the Walk-Away Time

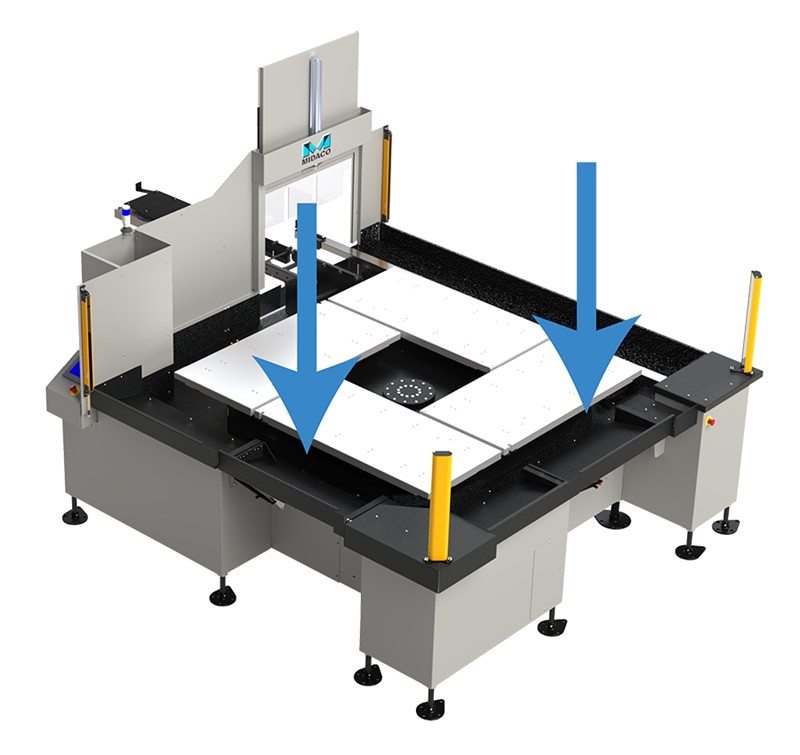

Conveniently access all 4 pallets from loading stations located on two (2) sides of the shuttle. Easily load and unload parts onto pallets with a crane or robot without any overhead obstruction.

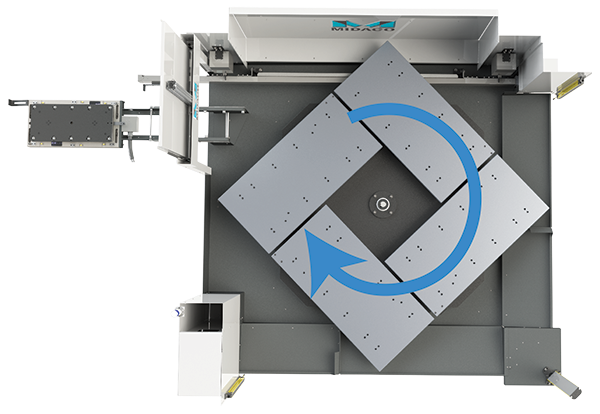

Full 360 degree rotation of the shuttle's pallet carrousel.

Once a job cycle is complete, pallets will rotate automatically on the shuttle carrousel, ready and scheduled to feed your VMC for multiple hours of unattended machining.

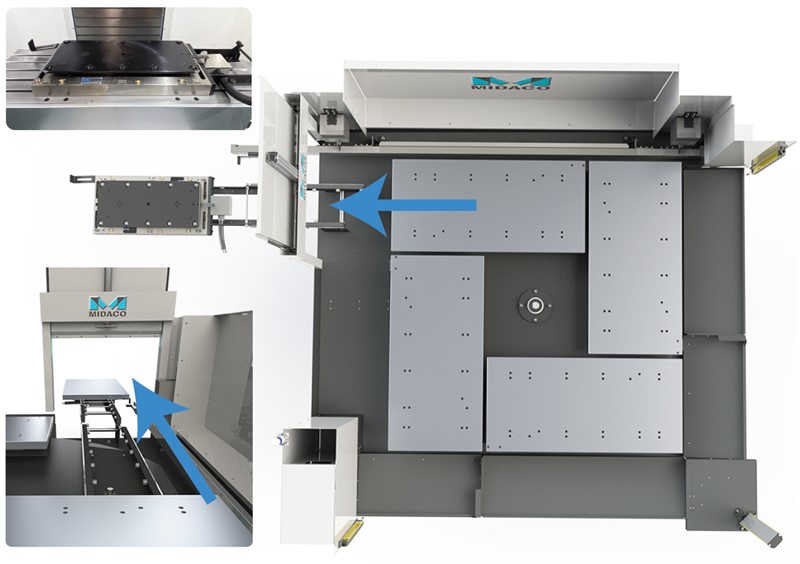

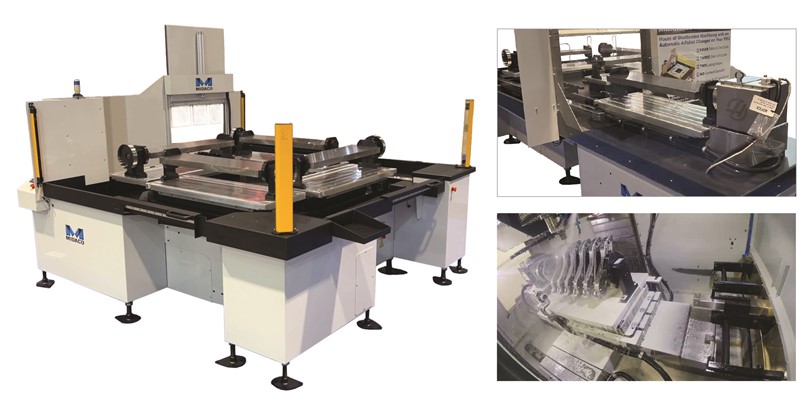

Durable precision ground steel rails and hardened locating pins/bushings assure +/- 0.0001” (0.0025mm) repeatability.

The shuttle's servo drive transfers the next pallet onto the cast iron receiver mounted directly onto the machining center table.

The shuttle's servo drive transfers the next pallet onto the cast iron receiver mounted directly onto the machining center table.

Specifications:

- 1- servo drive shuttle system with automatic door and light curtain.

- 4 - cast aluminum or cast iron pallets sizes from 28" x 15" (711mm x 381mm) up to 50” x 24” (1270mm x 609mm).

- 1 - cast iron receiver starting with 500 lb (226 kg) capacity per pallet on smallest model, up to 2,000 lb (908 kg) weight capacity per pallet on largest model {with weight evenly distributed}.

- Control panel is fully integrated with the VMC via M-codes.

Light Curtain Guarding

But it’s not just about efficiency — safety is our top priority. The Automatic 4-Pallet Changer is equipped with advanced Light Curtain guarding. Using a light emitter, mirrors, and sensors, the system creates an invisible shield around the shuttle. If these beams are breached while the rotary table is turning, the pallet change halts immediately, ensuring maximum protection for your operators.

Efficient, safe, and smart—Midaco’s Automatic 4-Pallet Changer is designed to keep your production running smoothly and securely.

Enhanced Workholding Flexibility with Trunnion System for 4th-Axis Machining

For added versatility, MIDACO’s Automatic 4-Pallet Changer can integrate an optional Trunnion System that enables 4th-axis operations on a 3-axis VMC. Equipped with four trunnions, the system uses a single 4th-Axis Rotary Indexer (not included) to power all trunnions, and eliminates any need for cable management, simplifying the process. This feature is ideal for shops handling parts with complex geometries, angled surfaces, or multi-sided components, making it possible to perform intricate work in a single setup. The included actuator assembly provides smooth, reliable trunnion movement and straightforward operation. The Trunnion System minimizes operator intervention, boosting throughput.

"Dual" Automatic 4-Pallet Changer

MIDACO's Automatic 4-Pallet Pool is also available as a "Dual System" with one shuttle mounted on each side of the VMC, supplying a total of 8 pallets.