Load Big Parts Without Slowing Your Machines with MIDACO Automatic Pallet Changers

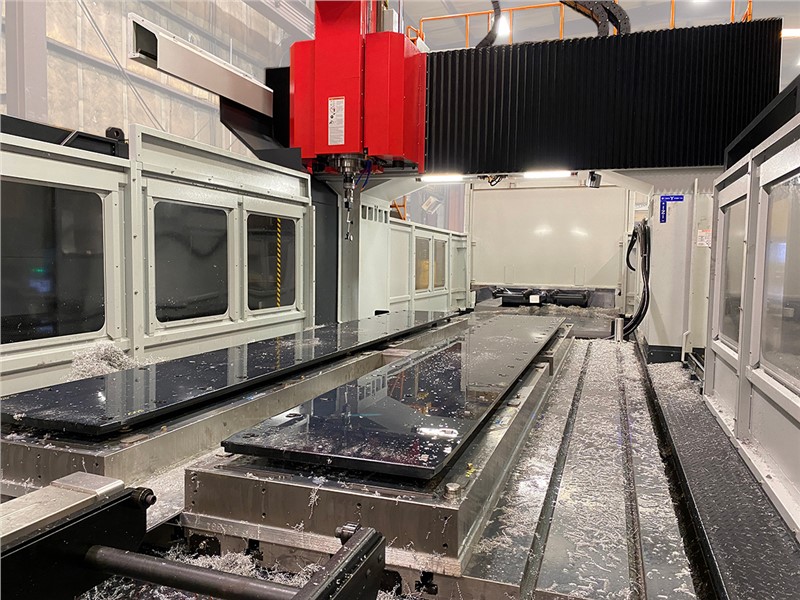

For factories machining large aerospace structures, automotive dies, aero-defense components, and other oversized parts, the machining center is one of the most valuable assets on the shop floor. Yet, too often, these multi-million-dollar machines sit idle—not because of programming delays, but because operators are loading and fixturing large workpieces directly inside the machining envelope.

“Every minute a CNC spindle isn’t cutting is time and profit lost,” says MIDACO. “Our Automatic Pallet Changers are designed to eliminate that wasted time by keeping your machine cutting while you prepare the next job offline.”

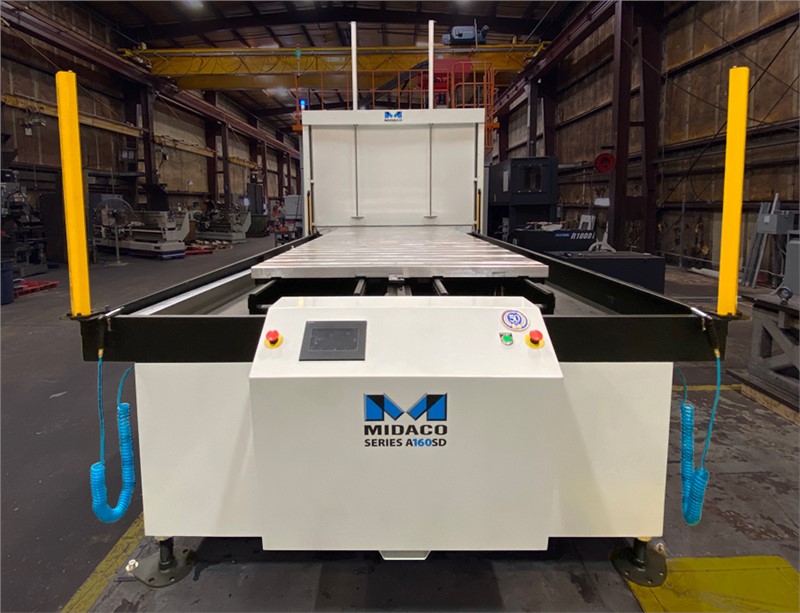

What Is an Automatic Pallet Changer for Large CNC Machines?

An Automatic Pallet Changer (APC) is a shuttle system that allows manufacturers to load and unload workpieces outside the machining center while the CNC spindle is still cutting on another pallet. Once machining is complete, the system exchanges pallets automatically, minimizing downtime.

This is especially critical for large vertical machining centers (VMCs) and bridge mills, where overhead cranes and gantries are used for part loading. With a MIDACO APC, there’s no overhead obstruction—operators can safely and ergonomically load heavy parts without climbing inside the machine or waiting for a crane opening.

MIDACO has been engineering Automatic Pallet Changers for Large-Scale CNC Automation for over 25 years — delivering proven reliability, precision, and productivity to machining centers worldwide.

How Does a Pallet Changer Improve CNC Machining Efficiency?

The core advantage is simple: spindle uptime.

- Offline Loading – While one pallet is in the machine, the alternate pallet is offline being loaded or unloaded.

- Seamless Exchange – Pallets switch quickly and the machine is not waiting for part change overs.

- Reduced Idle Time – Your machine spends more time cutting and less time waiting.

This means large-part machining operations gain more throughput per shift without expanding physical space or overextending on capital.

“Pallet changers allow shops to compete at the highest level of efficiency by turning machine idle time into profit-producing spindle time.” — MIDACO

What Sizes and Capacities Do MIDACO Pallet Changers Offer?

For manufacturers working with massive parts in aerospace, automotive, and defense industries, MIDACO pallet changers are engineered for both size and strength.

- Pallet sizes available up to 190" x 72" (4,826mm x 1,829mm)

- Load capacity up to 32,000 lbs (14,528 kg) per pallet (evenly distributed)

This scale makes them ideal for wing components, vehicle molds, structural parts, and heavy industrial equipment where traditional loading slows productivity.

Why Are Pallet Changers Important for Aerospace and Automotive CNC Machining?

Q: How do pallet changers benefit aerospace machining?

- Aerospace parts are often large, complex, and require long machining cycles. Pallet changers allow uninterrupted production while setups occur offline.

Q: Why are pallet changers valuable for automotive die machining?

- In automotive manufacturing, shorter lead times and rapid tool changes are critical. Pallet changers reduce downtime between cycles, helping meet production schedules.

Q: Are pallet changers suitable for defense and heavy-equipment machining?

- Yes. With 32,000 lb (14,528 kg) capacity per pallet with weight evenly distributed, MIDACO systems are built for the heavy structural and defense-grade components.

Ergonomic and Safety Advantages for Operators

Handling large parts isn’t just a productivity issue—it’s an ergonomics and safety challenge. MIDACO pallet changers reduce operator strain by:

- Eliminating the need to lean or climb inside machines for loading/unloading

- Allowing safe crane and gantry access without obstruction

- Enabling operators to prepare jobs at a comfortable working height

- Reducing fatigue and improving consistency in part handling

Types of MIDACO Automatic Pallet Changers

- Standard Automatic Pallet Changers – Single-shuttle system with two (2) pallets up to up to 150” x 39” (3810mm x 990mm) with 8,000 lb (3632 kg) load on capacity* each pallet for streamlined pallet exchange.

- Dual Pallet Changers – Two Shuttles: one on each end of the machine tool with two (2) pallets per shuttle (4 pallets total) for extended flexibility and efficiency. Up to 150” x 39” (3810mm x 990mm) with 8,000 lb (3632 kg) load capacity* on each pallet.

- Single/Dual Pallet Changers – Two shuttles: one on each end of the machine tool with one (1) large capacity* pallet per shuttle, up to 190"x72" (4826mm x 1829mm) pallet size and a qty of four (4) receivers totaling 32,000 lb (14,528 kgs) capacity* balancing footprint with productivity.

- Y-Axis Shift Pallet Changers – Single shuttle system with two (2) pallets up to 150"x50" (3810mm x 1270mm) pallet size and 8000 lb (3632 kgs) capacity* designed for machines which do not move in Y-axis. Pallets shift in “Y” on the MIDACO shuttle and enter the machine.

Key Specifications of MIDACO Automatic Pallet Changers

- Pallet sizes up to 190" x 72" (4,826mm x 1,829mm)

- Capacity up to 32,000 lbs (14,528 kg) per pallet (evenly distributed)

- Quick pallet exchange time depending on weight of parts on the pallet

- Configurations: Standard, Dual, Single/Dual, Y-axis Shift

- Compatible with new or existing VMCs and bridge mills

The Bottom Line: More Parts, Less Idle Time

In today’s competitive manufacturing landscape, time saved equals profit earned. For companies machining large-scale parts, the ability to keep the spindle cutting while parts are loaded offline is no longer optional—it’s essential.

MIDACO Automatic Pallet Changers provide proven ROI through:

- Increased spindle uptime

- Reduced operator fatigue

- Faster throughput and delivery schedules

- Flexible integration with existing machining centers

Comments