Today, KWM Gutterman, Inc. is the #1 producer of gutter machines in the USA, and this family-owned and operated business in Rockdale relies on MIDACO to get the job done.

KWM Gutterman’s mechanical engineer, Max Tucker, has spent roughly the past decade helping guide the company’s expansive growth in fabrication, made possible by the implementation of MIDACO co-operative automation.

KWM Gutterman’s mechanical engineer, Max Tucker, has spent roughly the past decade helping guide the company’s expansive growth in fabrication, made possible by the implementation of MIDACO co-operative automation.

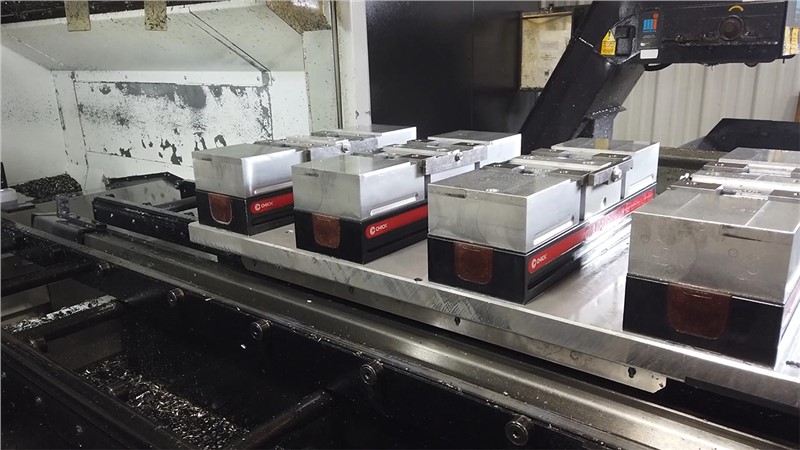

“When I started in 2013, we had a total of four lathes and four mills. We have now grown to eight mills, and we’re at 12 lathes. It’s been a wild ride. We’ve incorporated the MIDACO Pallet Changers. We’re at three of those now. Those have immensely brought production through the roof for us.“

The machine is no longer waiting for parts — back to machining in 30 seconds

Double Production

Regarding retrofitting a MIDACO Pallet Changer on his new Okuma machine, Tucker says the results have spoken for themselves.

“It’s been a lot of fun." - Max Tucker, Mechanical Engineer at KWM Gutterman, Inc.

Video Credits:

Tony Gunn of MTD CNC North America

https://mtdcnc.com/#/North-America

KWM Gutterman, Inc.

795 South Larkin Avenue

Rockdale, IL 60436 USA

(815) 725-9205

https://www.kwmgutterman.com/

Comments