Ability Metal Amplifies Productivity with Automation from MIDACO

MIDACO’s pallet changer made the difference on existing VMCs

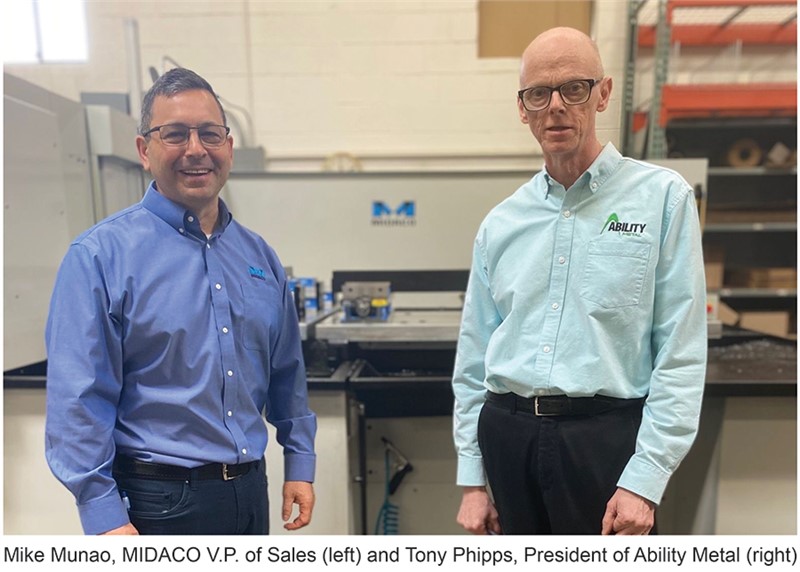

Tony Phipps, President of Ability Metal, said adding the MIDACO AS5025SDR4 4-Pallet Changer has been “a huge change,” creating a level of automation that allows machines that had previously been low-performing to run almost continuously.

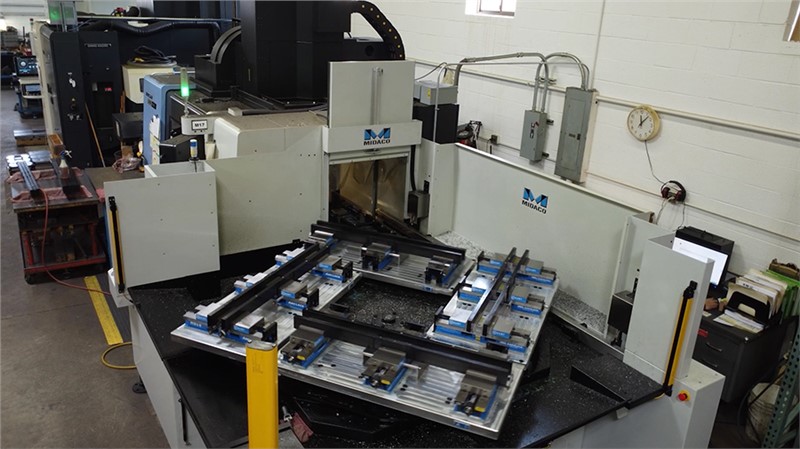

This Automatic 4-Pallet Pool will extend operator walk-away time and maximize productivity on a new or existing vertical mill by allowing the operator to change parts outside the VMC while the spindle is running, with 4 pallets on 1 shuttle (or 8-pallet Dual System with a shuttle mounted on each side of the VMC). Conveniently access all 4 pallets from either flip-panel station located on 2 sides of the shuttle. Easily load and unload heavy parts (up to 2000 lb capacity on each pallet) with a crane or robot without any overhead obstruction.

If you ask Ability Metal employee, Kevin Haderspeck, the difference on the floor has been significant.

"Basically now we are able to run four times as many parts. So instead of running for 10 minutes and then the machine is waiting for me to come over to change parts, I’m able to run for 40 minutes, essentially, and then walk over, change all four pallets (at once) and then walk away for another 40 minutes, where I go and do something else.”

Haderspeck said the difference goes beyond the extended periods of uninterrupted run-time MIDACO systems provide to machining centers, like Ability Metal’s existing DN Solutions (formerly Doosan) DNM-6700 from 2018.

Haderspeck said the difference goes beyond the extended periods of uninterrupted run-time MIDACO systems provide to machining centers, like Ability Metal’s existing DN Solutions (formerly Doosan) DNM-6700 from 2018.

“Before, we had to blow off the whole part from the machine, that took some time, now we're able to incorporate the MIDACO chip fan, which blows off the entire part inside the machine. Now I can walk up and the part is relatively clean. So I walk up, open the vices, pull the parts out, put new parts in, and we’re good to go. And the spindle can stay running the entire time.”

Streamline production on the floor

For Ability Metal, the incorporation of MIDACO’s 4-Pallet Changer System provides automation that lasts throughout the day, freeing up its workforce to focus on other tasks at hand and streamlining production on the machining floor.

“We had an 80-minute part, we subbed all three pallets, got one in and got the fourth pallet changed, and I can walk away for half the day and it will just run. I walk up again, halfway through my day, change parts, and I’m good before I go home.”

“I can make 300 of this part in two weeks, so if a customer calls and says they need x number parts, it will take them x-number of days. I can give them that information and they’ll be more satisfied.”

NOTE: MIDACO's Automatic 4-Pallet Pool is also available as a Dual System with one shuttle mounted on each side of the VMC, supplying a total of 8 pallets. (machine location not at Ability Metal)

The boss is always happy to see the green light on the machine.

“Definitely inside of work, it has been a lot more convenient. It’s easy to walk up, change a few parts and the machine stays running. I know the boss is always happy to see the green light on the machine, that’s always good to see.”

“We ordered another one for an existing Mori Seiki (DMG MORI) Dura Vertical from 2013, so we’re hoping to get that in the next few weeks and incorporate that into our production. We’re really excited about it.”

For more information on MIDACO Pallet Changers

Call or complete our online contact form today.

Watch Ability Metal's Full Success Story

Video credits:

Tony Gunn & MTD CNC North America

Ability Metal (formerly Ultra Specialties Inc.)

1360 Howard St., Elk Grove Village, IL 60007

ph: (847) 437-8110

Writing credits: Sam Scinta Jr - collaborator

Comments