Machining Excellence Added More Productivity with Fewer Man Hours

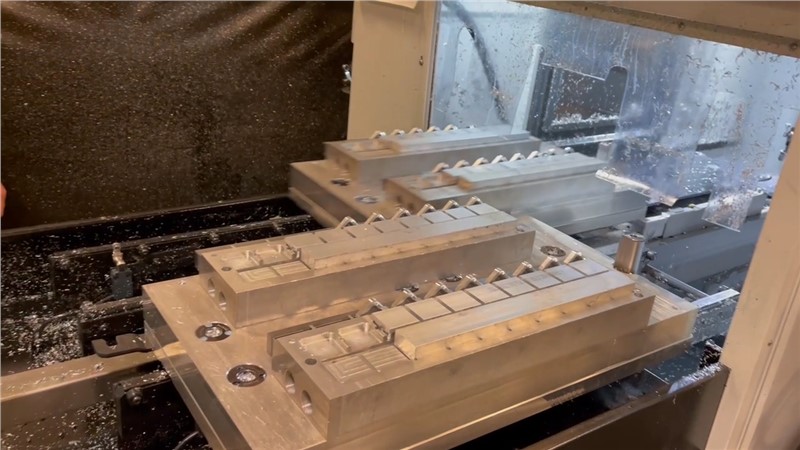

When Galyon Manufacturing needed to increase productivity for its operation in Sweetwater, Tennessee, it turned to new CNC equipment, quickly choosing a Haas DM2 for its speed and a MIDACO ADM-2SD for pallet changer automation. This combination of machining excellence added more throughput with fewer man hours, decreasing the strain on the operator in the process while seeing a 70% rise in machine tool productivity.

“It’s been a good experience,” Galyon Manufacturing Lead Programmer Patrick McClintock said of integrating the MIDACO APC with the Haas DM2. “It integrated easily with the Haas control and has given a huge boon to our productivity. Easy to program and easy to use, the MIDACO APC has been such a good piece of equipment. I’m very glad we invested in it.” - From left to right: Mark Wargo, Programmer; Bill Walsh, Sales - HAAS Factory Outlet - Div of Phillips TN; Dustin Braden, Operator; Patrick McClintock, Lead Programmer.

“HAAS and MIDACO solved our challenge.” - Galyon Mfg.

About Galyon Manufacturing

Galyon Manufacturing also performs precision surface cylindrical and jig grinding, and heat treating, working with CNC laser, plasma and waterjet, while also using manual mills and lathes. They can attain up to four-axis milling in addition to two-axis, live-tool and subspindle tuning.

Galyon Manufacturing employs roughly 45 people

in Sweetwater, Tennessee and was founded in 1984 by Verlin “Buddy” Galyon, a

30-year veteran of the Y-12 National Laboratory in Oak Ridge, Tennessee. Galyon

Manufacturing later became incorporated in 1994.

For more information on Midaco Pallet Changers

Call or complete our online contact form today.

MIDACO

Corporation

2000 Touhy

Ave

Elk Grove

Village IL 60007

(847)

593-5668

Haas Factory Outlet - Tennessee

A Division of Phillips

663 Ken Pilkerton Dr

Smyrna, TN 37167

(336) 665-1080

Galyon Manufacturing

650 County Road 326

(423) 337-5343

Sweetwater, TN 37874

Comments