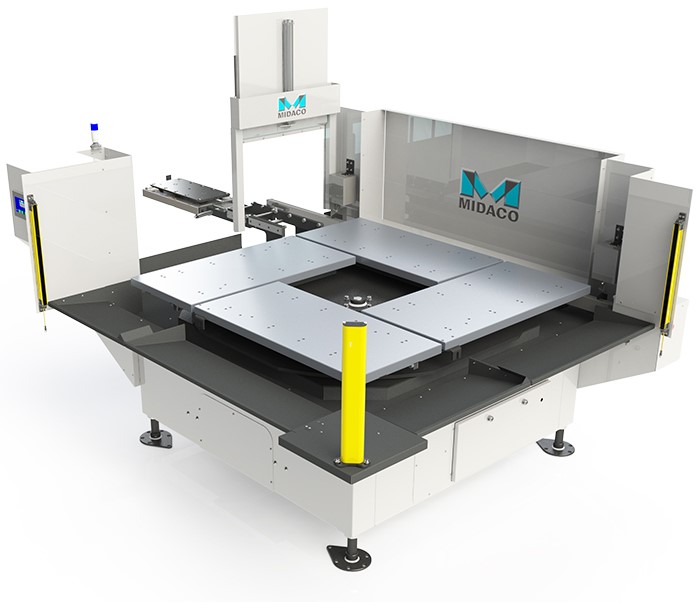

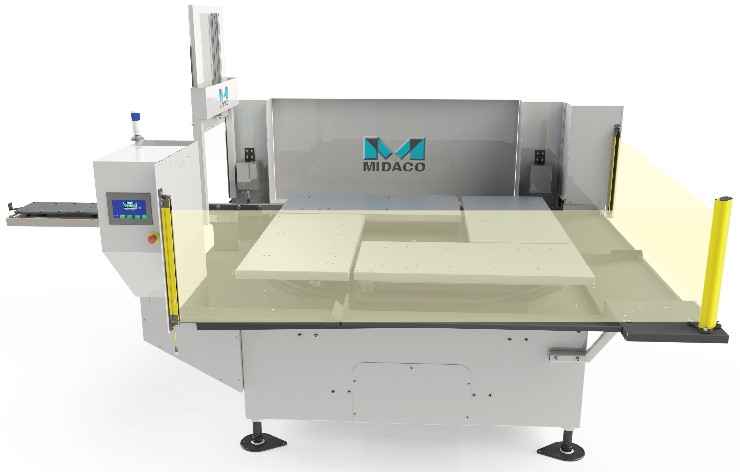

Whether running high volume production of the same part or programming several different set-ups, MIDACO's Automatic Rotary 4-Pallet Changer will extend operator walk-away time and maximize productivity on your new or existing vertical mill with 4 pallets on 1 shuttle. Save money by increasing spindle utilization during the machining process and quote more competitively.

ONE Shuttle + FOUR Pallets = QUADRUPLE the Walk-Away Time

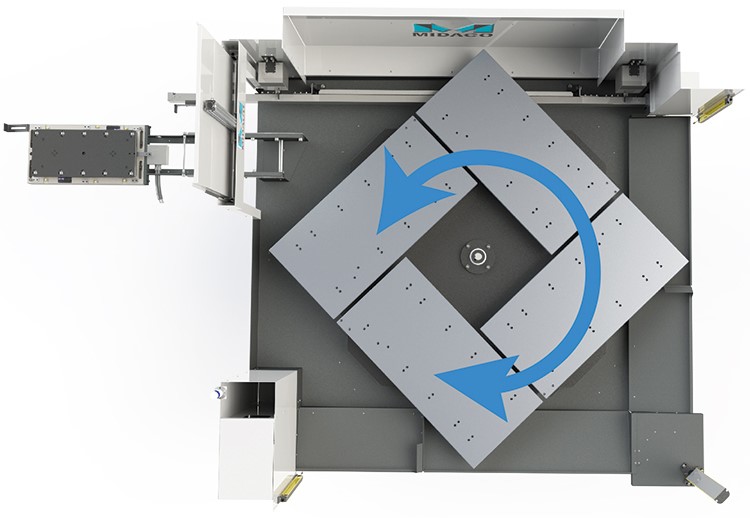

Full 360 degree rotation of the shuttle's pallet carrousel in either direction.

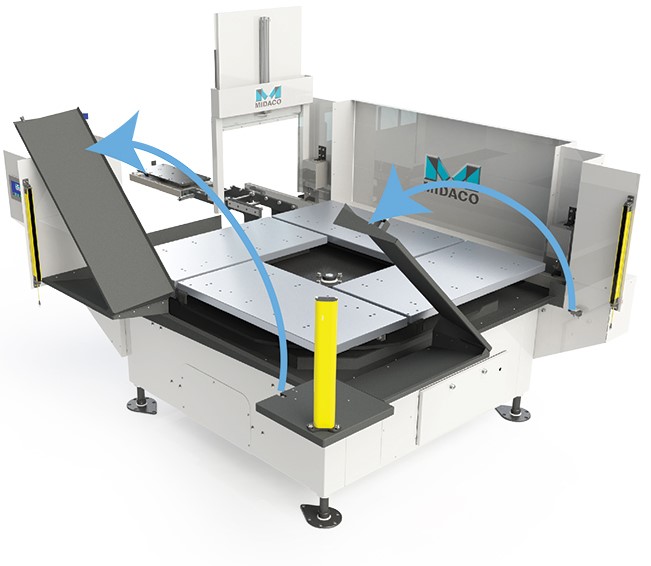

Once a job cycle is complete, pallets will rotate automatically on the shuttle carrousel, ready and scheduled to feed your VMC for multiple hours of unattended machining.

Once a job cycle is complete, pallets will rotate automatically on the shuttle carrousel, ready and scheduled to feed your VMC for multiple hours of unattended machining.

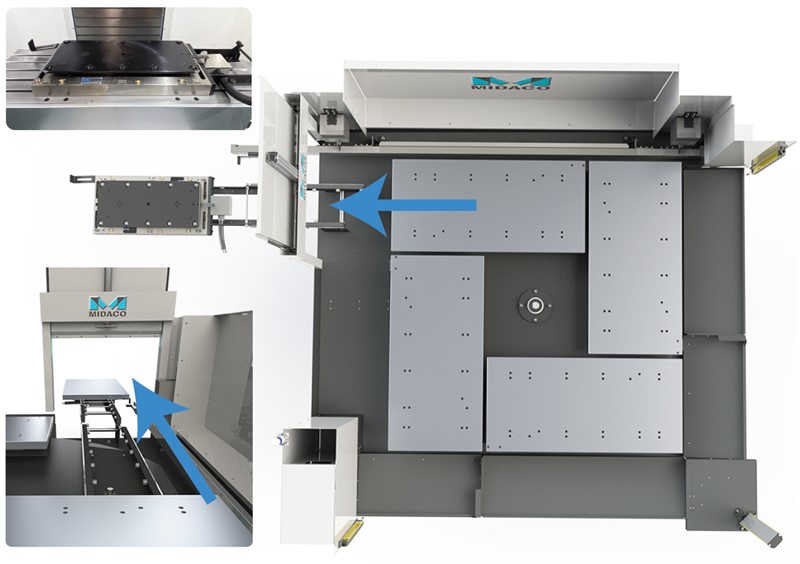

Durable precision ground steel rails and hardened locating pins/bushings assure +/- 0.0001” (0.0025mm) repeatability.

The shuttle's servo drive transfers the next pallet onto the cast iron receiver mounted directly onto the machining center table with +/- 0.0001” (0.0025mm) repeatability.

The shuttle's servo drive transfers the next pallet onto the cast iron receiver mounted directly onto the machining center table with +/- 0.0001” (0.0025mm) repeatability.

Specifications:

- 1- servo drive shuttle system with automatic door and light curtain.

- 4 - cast aluminum or cast iron pallets size 50” x 19" - 24” (1270mm x 482 - 609mm).

- 1 - cast iron receiver with up to 2,000 lb (908 kg) weight capacity per pallet {with weight evenly distributed}.

- Control panel is fully integrated with the VMC via M-codes.

CE Light Curtain

With 2-sided guarding via a light emitter, mirrors and sensors, a pallet change will not occur if the invisible light beams surrounding the shuttle system are breached. Meets CE compliance.

See Model Sizes and Pricing

For more information Call or complete our online contact form today.

Comments