MIDACO Pallet Changers Running Production at the HAAS Factory in Oxnard CA.

We're taken on a full tour of the HAAS factory in Oxnard, CA hosted by Andrew Harnett, Mfg. Engr., with a glimpse of how MIDACO's Automatic Pallet Changer Systems have been added to their own CNC machining centers. (timestamp 19:40 - 21:13)

"... you’re carrying multiple parts so you can keep the spindle turning the entire time. You’ve got one part staged, one part being machined so you keep that spindle turning."

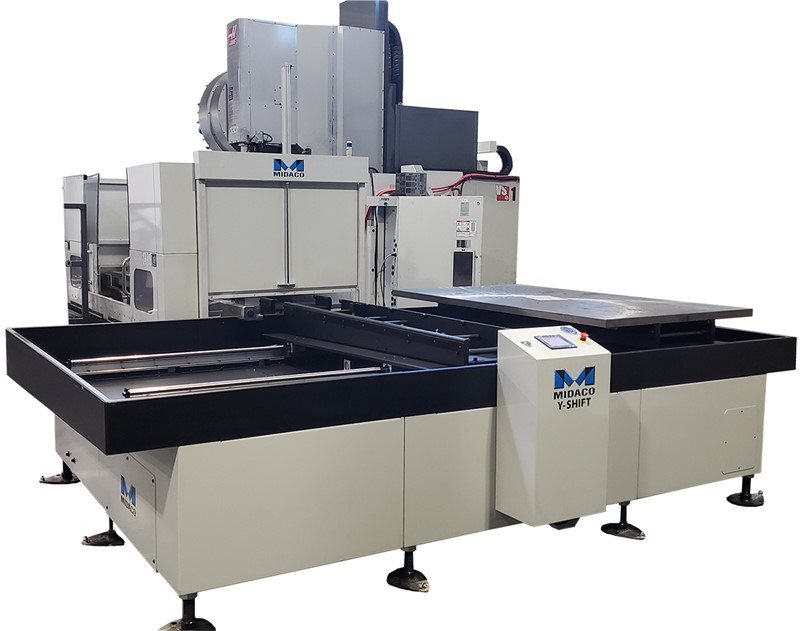

MIDACO's A80SD Automatic Y-Axis Shift Pallet Changer, equipped with two (2) cast aluminum pallets (cast iron also available), allows for part staging outside the VS3 on one of the pallets while the spindle is milling parts loaded on the other pallet inside the machining center. As the cycle ends, these parts are then automatically moved along the Y-axis on the MIDACO shuttle and the pallets are switched onto the cast iron receiver mounted on the machine tool table. Cutting is resumed with minimal spindle idle time.

MIDACO Pallet Changers for Maximum CNC Spindle Utilization

Guiding us along the factory floor, Harnett points out additions they've made to their existing VS systems. "These cells are an example of how we do medium volume, medium size castings and keep the spindle turning as much as possible. Here we’ve married up… we’ve got a whole bunch, like 7, of these cells and typically it’s a VS3 married up to one of these MIDACO Pallet Changers.

We run two different things here… medium size lathe bases, small lathe bases, and on some of the other cells we run medium and small VMC castings."

"We’ve been running these VS3 cells for easily more than a decade, but more recently we’ve teamed those up with MIDACO pallet changers."

HAAS Automation, Inc. knows the value of every moment a machine tool spindle is making chips. To

get the most productivity out of several machining centers in their own facility,

HAAS has chosen to incorporate MIDACO Automatic Pallet Changers into their own CNC machining process.

For more information

Call or complete our online contact form today.

Comments