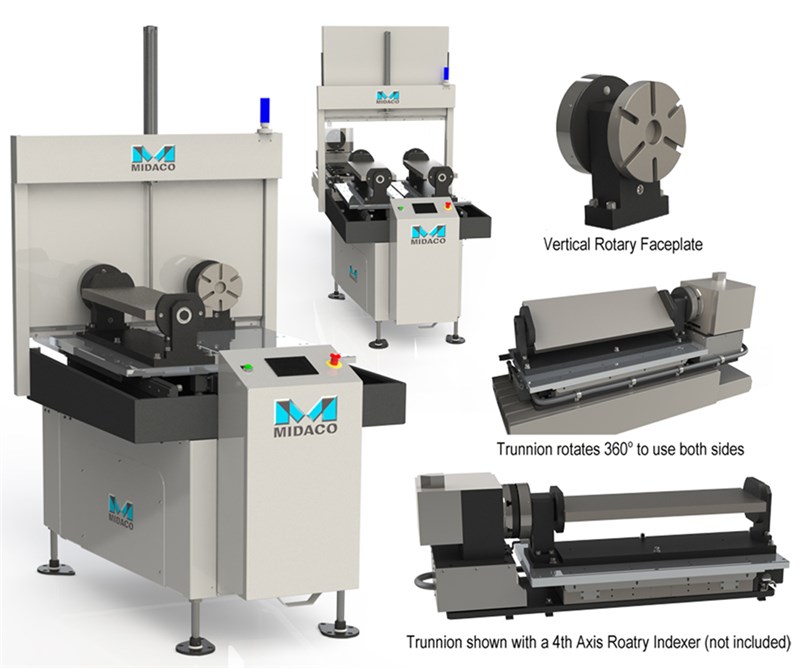

ONLY ONE 4th Axis is required to get the benefits of a Horizontal Machining Center on a Vertical Machining Center. Increase the 4th Axis productivity by adding our Trunnion System and Vertical Rotary Faceplate to an Automatic Pallet Changer on a VMC equipped with a Rotary Indexer.

The MIDACO TRUNNION SYSTEM includes one 4th Axis actuator assembly and two trunnions (individual trunnion is also available separately), and works with any 4th Axis rotary-indexer (not included). A trunnion is mounted on each pallet of the Pallet Changer outside the VMC. Once transferred into the machining area, the trunnion clamps onto the MIDACO receiver and automatically engages with the 4th Axis. The Trunnion System is a cost effective solution to increase your Vertical’s capability by machining 360 degrees without the need for cable management. Increase your machining versatility by adding a VERTICAL ROTARY FACEPLATE ASSEMBLY, which is also mounted on a pallet, for multiple workholding options. NO CABLE MANAGEMENT NEEDED! Go to Trunnion Series page

See how MIDACO's NEW Trunnion System can make your VMC more versatile at HAAS Tec 2017.

HAAS Automation, 2800 Sturgis Rd., Oxnard CA, October 10-13.

Comments