Considering Automation on Your VMC?

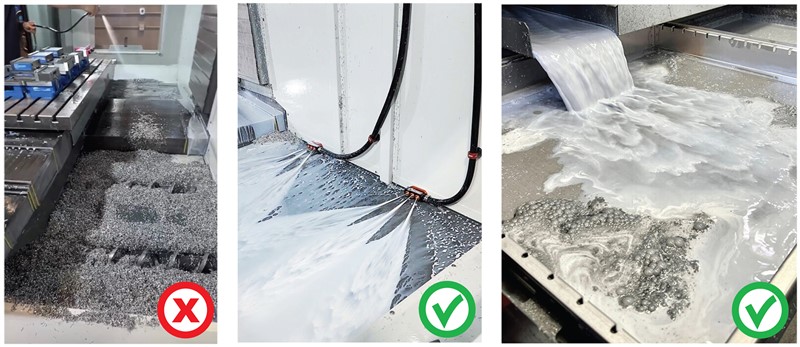

Effective chip management is key to lights-out machining with your MIDACO Pallet Pool or robot machine-tending applications. All machines require proper chip flow, but keeping up with necessary chip maintenance can slow down production. Keep the chips moving and the machine cutting with a CNC Chip Washdown System.Washdown Pump

With a high-volume pump, stainless steel components and robust design, this system is built to withstand the rigors of industrial machining environments, providing long-term performance to keep your machines running smoothly.

Pump dim. 28”x16”x16” (711 x 406 x 406 mm)

The ultra-flexible hose offers versatility in nozzle placement. Magnetic hose clamps provide secure attachment and easy adjustment, facilitating hassle-free installation and maintenance. The included crimping tool ensures secure connections.

Washdown Spray

Includes Stainless Steel Filter Tray

- CWS/55 (32” x 28” x 4”) for 55-gallon sumps

- CWS/95 (32” x 32” x 8”) for 95-gallon sumps