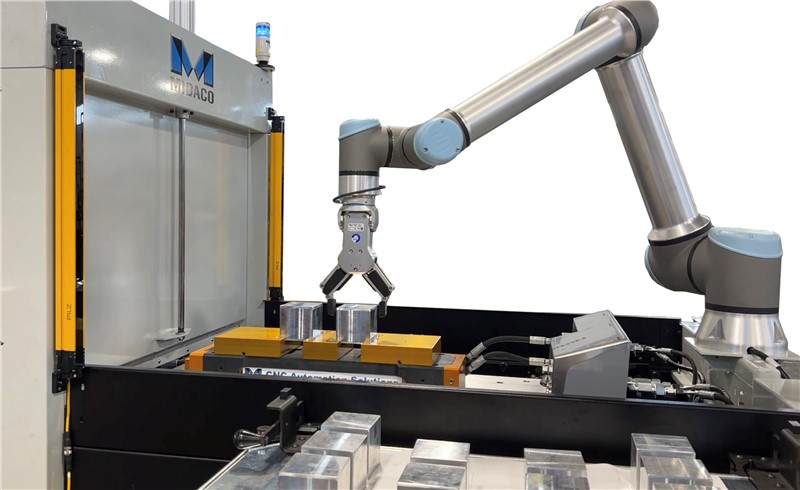

MIDACO has put together a “robot-ready” package of Automatic Pallet Changers to take the complexity out of automated CNC machine tending and part loading.

Critical labor shortages call for creative automation solutions such as adding collaborative robots to increase unattended machining. But why set up a robot to load parts one by one directly onto your vertical machine tool table and lose valuable cutting time? Instead, your robot can load a pallet full of parts on a MIDACO Automatic Pallet Changer while the CNC machine is cutting. Read the full article in Modern Machine Shop.

Two Forms of Machining Automation Are Better Than One

The cobot-fed Automatic Pallet Changer is designed for vertical machining centers (VMCs) ranging from approximately 22"x15" (558mm x 381mm) up to 64"x31" (1626mm x 787mm) XY travel. The shuttle’s front control panel is customized to mount and integrate with the end-user’s choice of cobot, which is to be purchased separately from an authorized dealer. This system comes standard with two aluminum pallets and can be mounted on either the left or right side of the machining center.

Pallet sizes for XY travel from 22"x15" up to 64"x31"

Easily integrated to the machine tool via M-codes, the shuttle is servo driven and automatically switches pallets in approximately 15 seconds depending on combined part weight on the pallet. A cast-iron pneumatic receiver is mounted directly onto the machine tool table — hardened locating pins, ground bushings and hardened pallet rails ensure a repeatability of ±0.0001" (0.0025 mm). Each pallet’s weight capacity ranges from 500 lbs to 2,000 lb depending on pallet size; however, the individual part weight depends on the cobot’s payload capacity.

Repeatability of ±0.0001" (0.0025 mm)

Automated Workholding without Hose Management

Combined with Midaco’s Hydraulic Docking System on the pallets, the robot/cobot can load parts on the pallet changer outside of the VMC unattended while the spindle is cutting, freeing the operator to perform other tasks. The hydraulic vises are automatically clamped/unclamped and transfer into the machining center without the need for hose management. The vises will stay charged on the pallet while in the machine tool. Once the cycle is complete the pallet exits the machine, docks into place on the shuttle, vises release and the cobot can load a new set of parts while the alternate pallet is in the VMC being milled. Machining time is limitless and only dependent upon how many blanks can be set-up within the robots reach on side carts or conveyor systems.

VMC Automation Made Simple

The enduser can use their own robot/cobot and hydraulic workholding or have Midaco provide additional automation solutions to the standard package, including a robot or cobot arm (does not include end of arm tooling or programming of robot); hydraulic 6" double-station vises; loading carts; three-sided light curtain safety guarding composed of light emitters sensors and mirrors.

Take advantage of price discounts offered with a “Robot Ready” package set-up vs purchasing individually.

"Robot Ready" Automatic Pallet Changer Package includes:

- Automatic Pallet Changer from series A16SD, A30SD, A40SD, AS50SD, A50SD & A60SD

- Robot Ready Modification Mount (does not include robot)

- HDS3000 Hydraulic Docking System (does not include vises)

MIDACO requires robot/cobot specifications prior to this customized Automatic Pallet Changer order.

Package price depends on pallet changer size.

Note: Images and video show optional 3-Sided Light Curtain Guarding and Loading Carts.

Use your own robot/cobot and hydraulic workholding or contact MIDACO for these additional options:

- UR Cobot (does not include end of arm tooling or programming of robot.)

- Hydraulic 6" Double Station Vises

- Loading Carts

- 3-sided Light Curtain Guarding

For more information