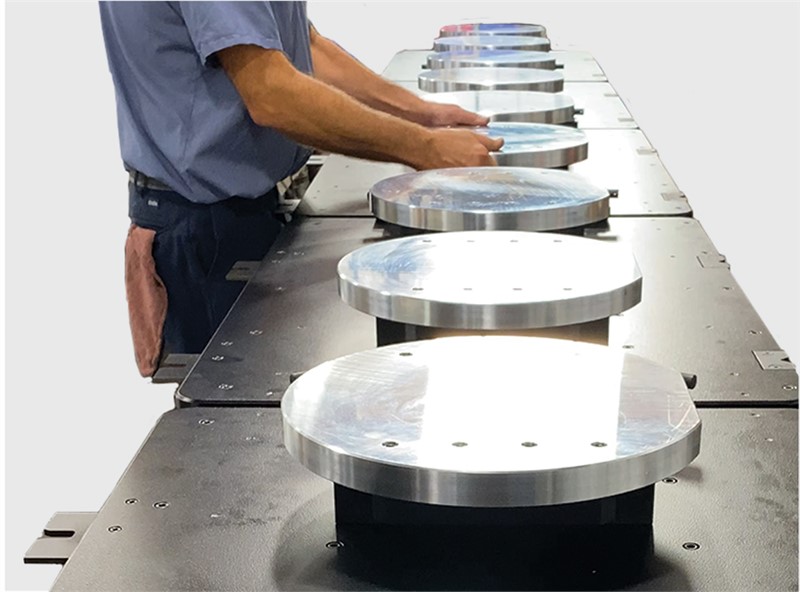

Automatic Pallet Changer "Pallet Pool" for 5-Axis Mills

![]() Use just one cart for a quick 2-pallet transfer or load a train of carts and go “lights-out”.

Use just one cart for a quick 2-pallet transfer or load a train of carts and go “lights-out”.

Hefty 150 lb (68kg) part weight capacity PER PALLET.

- Easily load and unload pallets onto carts without obstruction.

- Interlocked pallet carts are mobilized through the shuttle system on casters allowing the shuttle arm to continuously feed pallets into the 5-Axis machining center.

- Once a cart is pushed through the other side, the operator can easily load new pallets and change parts while the spindle is cutting.

- A completed pallet cart can be removed by unlocking the T-pins and rolled to a different location or to the opposite end of the train to keep production going.

- Depending on programming, after the full “pallet cart train” passes through the shuttle, the process repeats sending carts back in the opposite direction.

Specifications:

- 15” (381mm) dia. cast aluminum pallets.

- 150 lb (68kg) capacity per pallet.

- Cast iron receiver does not require air.

- +/- .0001" (.0025 mm) repeatability.

- Automated access door retrofit to the machining center.

- PLC is fully integrated with the machine.

Automatic Pallet Changer System with Carts includes:

1 – APCC15 Shuttle and Automatic Door (retrofit to the machining center)

1 – Cast Iron Receiver Base, 150 lb. (68 kg) capacity

2 – 15” (381 mm) dia. x 1.25” (31.75 mm) thick Cast Aluminum Pallets

1 – Pallet Cart* with interlocking T-pins (holds 2 pallets)

Light Curtain package with shuttle guarding via a light emitter, mirrors and sensorAdditional carts* and pallets sold separately