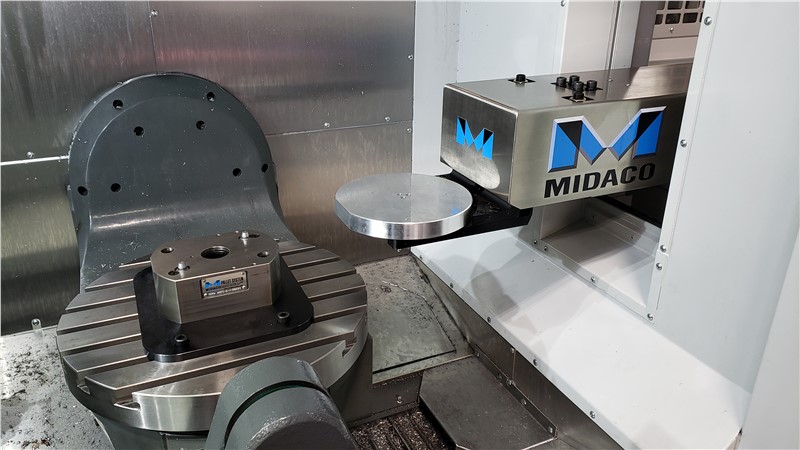

Automatic Multi-Pallet Changer Pallet Pool for 5-Axis Machining Centers

Manufacturers around the world understand that a key to remaining competitive in a global economy is to decrease downtime and increase productivity. MIDACO provides solutions that do just that. Particularly with Aerospace and Defense manufacturing becoming more competitive, making the machining process more efficient will reduce the cost per man hour per piece which helps manufacturers compete with lower cost labor countries. The Automatic Multi-Pallet Changer pallet pool will improve efficiency on new and existing 5-Axis and standard Vertical Machining Centers (VMCs). Our pallet changers exceed international standards with optional CE guarding and are UL listed so they can be used anywhere in the world. AMPC Brochure PDF

Manufacturers around the world understand that a key to remaining competitive in a global economy is to decrease downtime and increase productivity. MIDACO provides solutions that do just that. Particularly with Aerospace and Defense manufacturing becoming more competitive, making the machining process more efficient will reduce the cost per man hour per piece which helps manufacturers compete with lower cost labor countries. The Automatic Multi-Pallet Changer pallet pool will improve efficiency on new and existing 5-Axis and standard Vertical Machining Centers (VMCs). Our pallet changers exceed international standards with optional CE guarding and are UL listed so they can be used anywhere in the world. AMPC Brochure PDF

Making machining more efficient reduces the cost per man hour per piece which helps manufacturers compete with lower cost labor countries.

Benefits of MIDACO's Automatic Multi-Pallet Changers include:

Benefits of MIDACO's Automatic Multi-Pallet Changers include:

- "Lights Out" 5-Axis machining.

- Workpieces easily loaded outside the machine while its cutting.

- Increased operator productivity.

- More efficient machining process.

- Pallets easily interchange between machines or departments.

- Exchange pallet in seconds with a +/- .0001" (.0025 mm) repeatability meeting the standard for complex parts with tight tolerances.

For more information

Call or complete our online contact form today.

- image credits FIMS Manufacturing, NJ