Small Shop, Big Growth: Apogee Manufacturing Steps Into High-Volume CNC

Production

Apogee Manufacturing Solutions, a growing machine shop based in New Holland, PA, has

built a solid reputation delivering precision-machined components in prototype

and low-volume quantities. Until 2020, their projects typically ranged from

one-off prototypes to short production runs of up to 250 parts. But when a

long-standing customer presented them with a major new opportunity—high-volume

production reaching into the tens of thousands of parts per year—

Apogee faced a

challenge familiar to many small shops:

how to scale without

expanding physical space or overextending on capital.

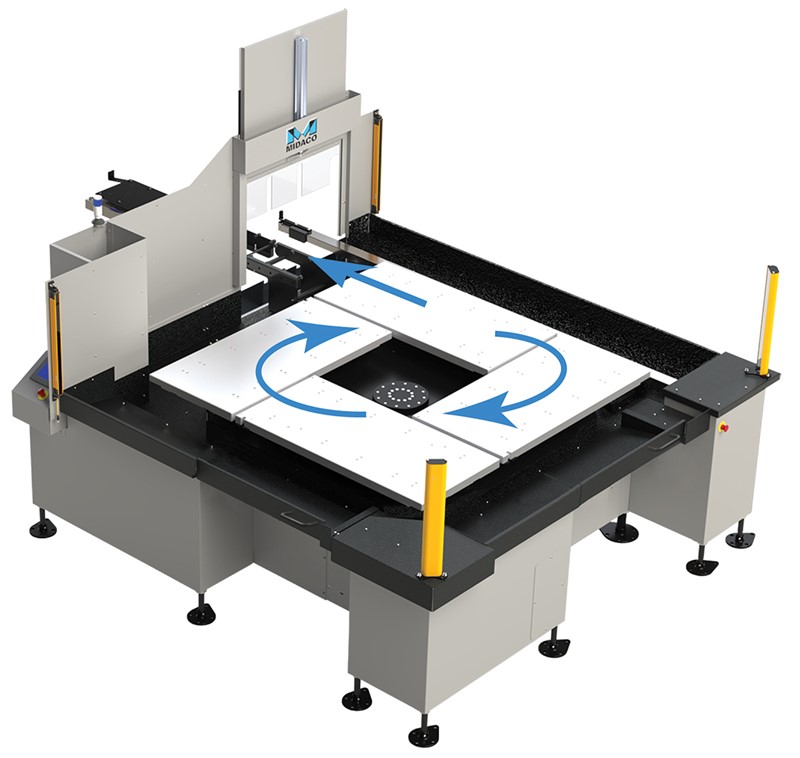

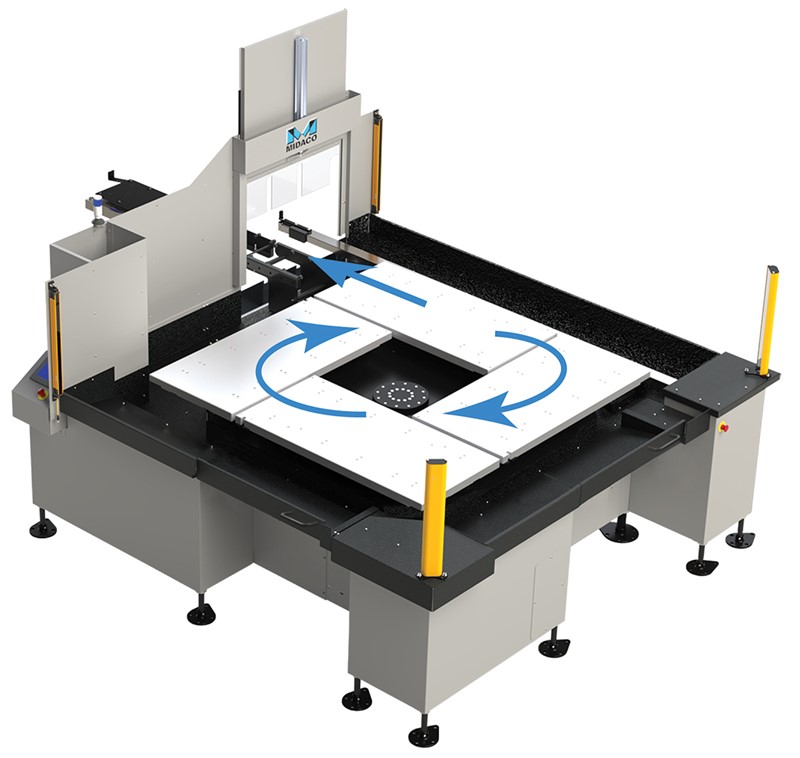

Note: MIDACO Automatic Rotary 4-Pallet

Changer shown with 2-sided light curtain guarding and a side panel on the right

of image. Newer models are designed without

a side panel and provide 3-sided CE light curtain guarding.

Smart Scaling With Limited Shop Floor Space

![]()

“Our current location is very limited

on space, and we have a very conservative risk position for capital

expenditures,”

Apogee shared. That meant adding a second machine or

expanding the facility wasn’t an option. However, productivity had to increase,

and efficiency had to improve.

That’s when a machine tool vendor suggested looking into

MIDACO’s pallet changing systems. After reviewing the product offerings on

MIDACO’s website, Apogee quickly realized the Automatic Rotary 4-Pallet

Changer (model AS5020SDR4 with four 50” x 19” {1270mm x 482.6mm} End Load Cast

Aluminum Pallets) was the solution they needed.

“It was clear that their product was a great option for

this opportunity,” they stated.

Tackling Complex Batch Production with Minimal Downtime

The specific job required machining several part

configurations in small rotating batches, each with its own unique fixture

setup that filled most of the Hurco VM30i’s

working envelope. Traditional setups and changeovers would have resulted

in substantial machine downtime between part runs.

“The MIDACO 4-pallet

changer enables us to machine all the designs with minimal down time and labor

for change-overs,” Apogee noted.

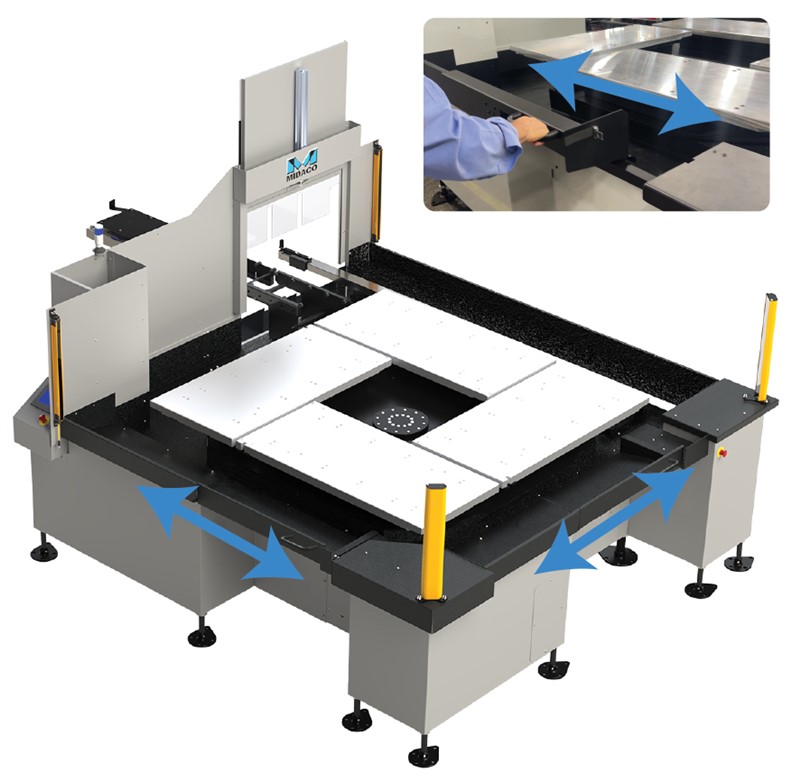

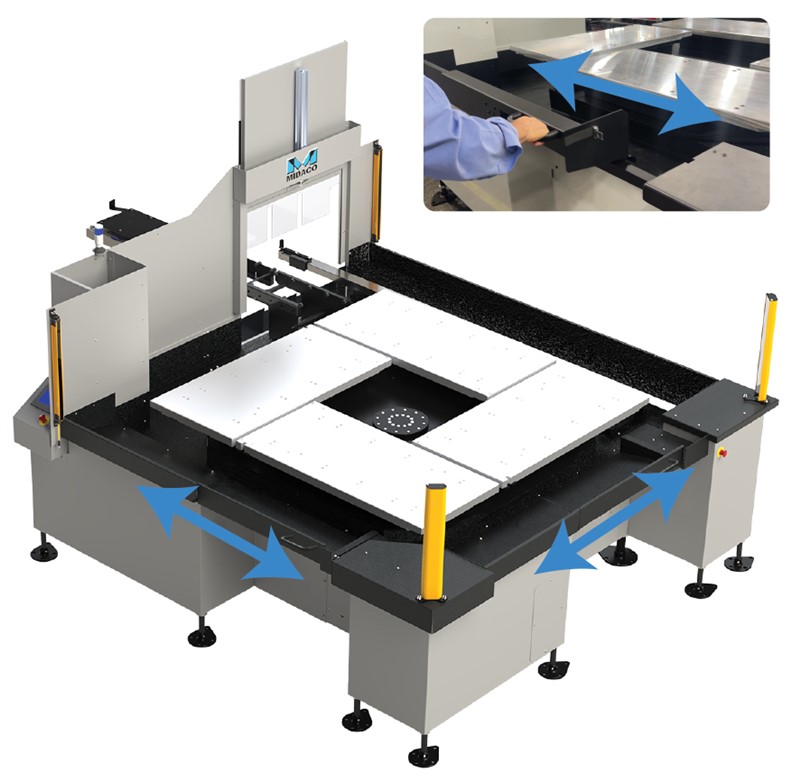

Since

MIDACO offers an option to purchase additional pallets

to the standard four which come with this model Pallet Changer,

Apogee configured

SIX dedicated pallets for their Hurco VM30i, which gave them the flexibility to

rotate between setups quickly and efficiently. The automatic pallet changer

drastically reduced the time spent manually swapping fixturing and parts

between jobs.

Increased Spindle Uptime by Nearly 50%

Beyond setup efficiency, the pallet changer offered another

significant benefit: increased spindle utilization. Operators could now load

parts on one pallet while the machine continued cutting on another, keeping the

spindle running consistently instead of sitting idle.

“This simple aspect increased our spindle up time by

almost 50%.”

![]()

This

dramatic improvement in CNC machine uptime helped

Apogee meet growing customer

demands.

Scalable

Productivity on Existing VMCs

With MIDACO’s

AS5020SDR4 Automatic Rotary 4-Pallet Changer,

Apogee Manufacturing was able to evolve from a low-volume job shop into a more

dynamic, high-throughput CNC operation.

Key Benefits:

- 50% increase in spindle uptime

- Reduced change-over labor

- Efficient small-batch rotation

- Flexible enough for both high-volume and prototype jobs

Doubling Down in 2025

As part volumes continued to rise, Apogee further optimized their CNC productivity by investing in a second MIDACO Automatic Rotary 4-Pallet Changer in 2025. This addition increased their capacity to manage production peaks and allowed them to run small prototype jobs on alternate pallets, maximizing the flexibility of their existing equipment.

Their decision to invest in a second pallet changer reinforces the long-term value and flexibility that

MIDACO systems bring to growing operations. For shops facing similar challenges, this case proves that the right automation upgrade can unlock big results.

Thinking about scaling your CNC productivity?

If your shop needs more output on existing machines, explore how

a MIDACO Automatic Pallet Changer can transform your workflow.

For more information on MIDACO Pallet Changers

Call or complete our online contact form today.

Comments