Giovanni Albanese of MTDCNC speaking with Mark Rattenberry, Managing Director at Mellish Engineering Services Ltd.

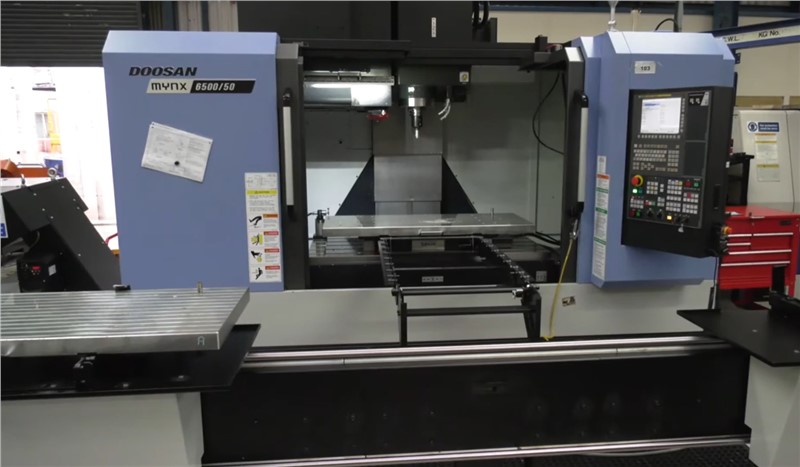

MIDACO Manual Pallet Changer Systems on DOOSAN Mynx6500 VMC

Equipping their Machining Centers with MIDACO Pallet Changers is a "No Brainer" according to Mark Rattenberry, Managing Director of Mellish Engineering Services Ltd. at one of their facilities located in Warsaw, Poland. In 2018 Mellish invested a whopping £900k GBP ($1.2 million USD) in machine tools to keep up up with market demands. The increased output has been a game changer.

Mellish made a smart investment in the MIDACO Manual Pallet Changer System—supplied by HYFORE Workholding Ltd.—installed on their Doosan Mynx 5600 Vertical Machining Center (VMC). Mark Rattenbury shares the dramatic improvements this system has brought to their shop floor.

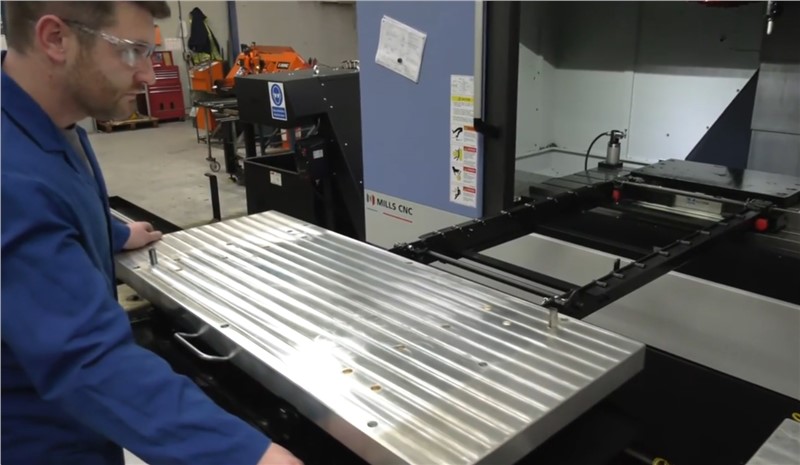

Eliminating CNC Downtime with Smart Automation

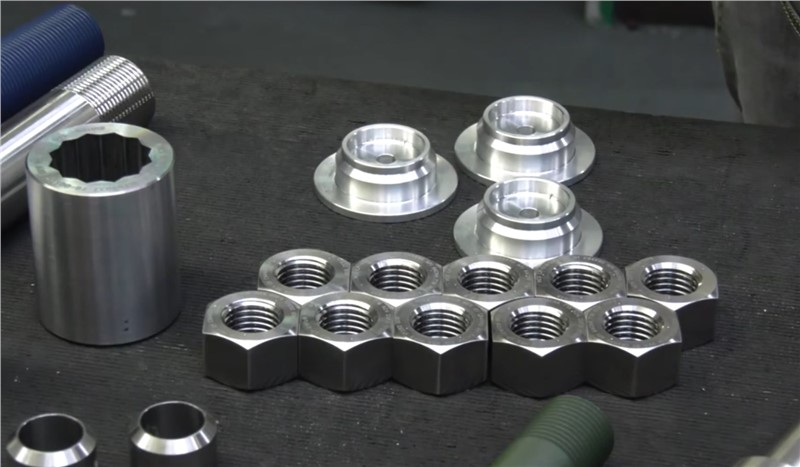

"We first bought the machine," said Mark, "and then we analyzed the loading times. We wanted to reduce them by loading a family of parts onto one bed and swapping pallets externally." The MIDACO system allowed Mellish to prep the next job while the machine was still running—virtually eliminating the downtime between cycles.

The results speak volumes:

“We normally machined a part in singles—20 minutes each. It took 10 minutes just to change parts. Now, using the pallet changer, we’ve reduced our cycle time so much that, over a batch of 200, we’re saving 40 hours a week.”

That’s not just more efficient—it’s transformational.

Fast ROI and Effortless Integration

“I’ve worked it out to a 12-month return on investment,” said Mark. “When you think about how often the doors are open on a VMC for changeovers, it's a no-brainer.”

With three BT40 vertical machining centers in their lineup, Mellish sees clear opportunities for expanding this productivity-enhancing solution even further.

Precision Loading and Heavy-Duty Capability

“We’ve got several jigs that we load outside the machine. Once they’re set, it’s just swap and go.”

Outstanding Support from HYFORE Workholding

Mellish’s journey into external pallet systems began with a simple inquiry about jigs. That quickly turned into a full solution, thanks to HYFORE's proactive support.

“I met HYFORE at an apprentice training center,” Mark explained. “Originally, I just wanted some jigs designed. Then Oli from HYFORE asked if I’d considered an external pallet system. Five minutes later, he had a YouTube demo up, and we were off.”

From design to installation, HYFORE impressed with technical expertise and flexibility.

“We worked with Darren to design the jigs, and they really thought of everything—from functionality to reducing cost. Brilliant service and excellent quality.”

Final Thoughts

The MIDACO Manual Pallet Changer has delivered on every front: reduced cycle times, improved machine utilization, faster changeovers, and a rapid return on investment. For Mellish Engineering Services Ltd., it’s not just a productivity upgrade—it’s a strategic advantage.

“If I’d known about this system earlier, I would have bought it sooner.”

Interested in increasing your CNC shop's productivity

like Mellish Engineering?

Discover how a MIDACO Pallet Changer System can transform your machining operations.

Call or complete our online contact form today.

Video Credits:

MTDCNC YouTube Channel for educational reviews in the Machine Tool Industry.

Mellish Engineering Services Ltd

Saville House

Middlemore Lane West

Aldridge, West Midlands WS9 8BG

United Kingdom

E: sales@mellishengineering.co.uk

T: +44 (0)1922 457799

Comments