GRIT-GRABBER™ Features & Advantages

- Sealed bearing, heavy duty industrial motor.

- Easily replaced filter traps vacuumed debris reducing operator hazards and improving shop cleanliness.

- Durable universal hose and clamps fits all models

- Illuminated RED ON/OFF switch.

- Vibration-free insulated enclosure operates with low noise level in 70dp (A) range.

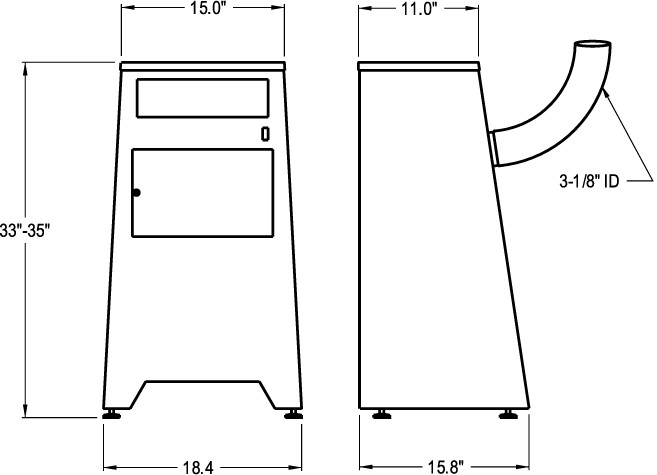

- Compact size utilizes available space in a tight area.

- Self leveling feet or stationary mount.

- CFM exhaust level exceeds OSHA’s minimum ventilation standard 1910.94 up to 10” diameter.

- Easy to retrofit saving time and labor.