Improve Shop Safety and Cleanliness with Midaco’s GRINDER-GUARD® and

GRIT-GRABBER™

A Smarter, Safer Solution for Bench and Pedestal Grinders

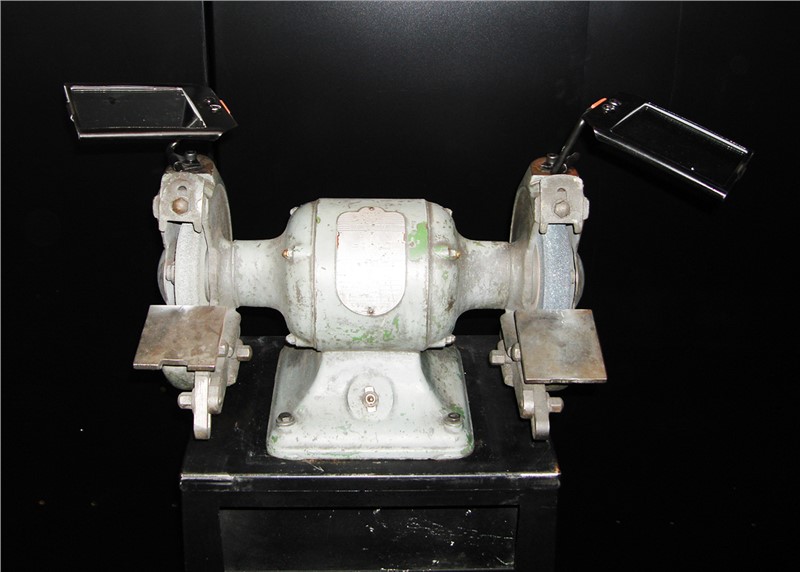

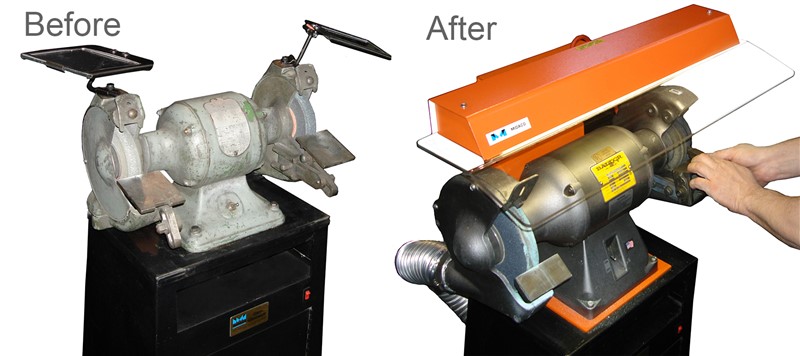

In many shops, the bench or pedestal grinder is placed in a distant corner—out of the way, but often out of sight. Poor lighting in these areas leads operators to flip up or entirely remove traditional grinder shields just to see their work. Unfortunately, this common practice creates a serious safety hazard. Add to that the clouds of grinding dust that spread across the shop floor, affecting air quality and leaving behind a trail of grit. PDF BrochureMidaco's Grinder-Guard® and Grit-Grabber™ system solves both problems — clearly and effectively.

The Problem:

- Shields Removed for Visibility – Flip-up guards are often moved or taken off by operators struggling to see their work.

- Poor Lighting Conditions – Grinders tucked into dark corners compromise visibility and safety.

- Dust and Debris Everywhere – Grinding operations create airborne particles and floor dust that travel throughout the shop.

- Lost Productivity – Inefficient use of shop grinders and buffers slows down productivity, ultimately resulting in lost time and greater cost.

The Solution:

Midaco GRINDER-GUARD® – LED Illuminated, Tamper-Resistant Shield

Engineered for bench and pedestal grinders from 7” to 12” in diameter, the GRINDER-GUARD® is a full-length, stationary shield made from chip-resistant polycarbonate. Unlike traditional flip-up guards, it is securely mounted beneath the grinder base—making it tamper-resistant and non-removable by the operator.

- Integrated Full-Length LED Light dramatically improves visibility during grinding operations.

- Fixed Design ensures shields remain in place to reduce the risk of injury.

- Universal Fit accommodates virtually all common grinders and buffers.

Midaco GRIT-GRABBER™ – Clean, Quiet Dust Collection

Pedestal

Grinding generates more than sparks—it throws fine dust and abrasive particles into the air. The GRIT-GRABBER™ pedestal and dust collection system captures this debris at the source, keeping your workspace clean and compliant with safety standards.

Powerful Sealed Bearing Motor with CFM exhaust exceeding OSHA minimum requirements.

- Quiet Operation promotes a more comfortable work environment.

- Triple-Stage Flame Retardant Filter captures fine dust with high efficiency and is easily cleaned or replaced.

- Spark Arrestor Screen prevents ignition hazards from hot metal particles.

Invest in Safety, Cleanliness, and Compliance