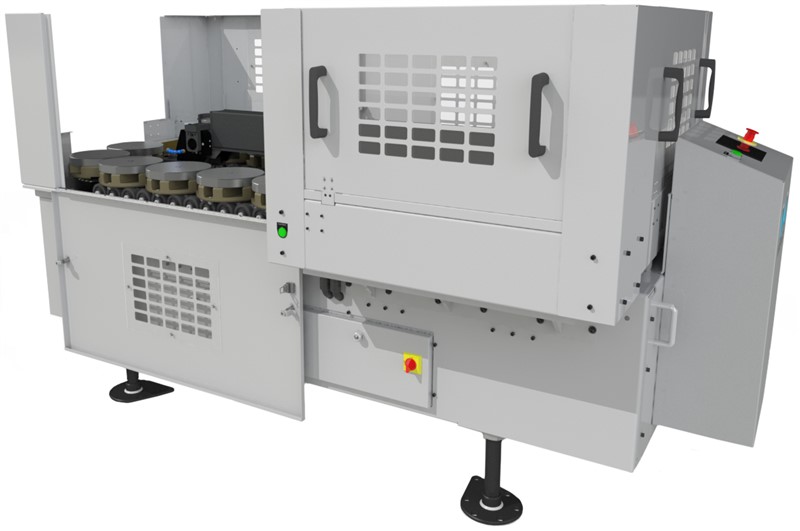

MIDACO Automatic Multi-Pallet Pool for 5-Axis Machining Centers

Increase Productivity. Reduce Downtime. Maximize Operator Efficiency.

The MIDACO Automatic Multi-Pallet Pool (AMPC) is engineered to help CNC manufacturers run longer, run smarter, and run unattended. By loading multiple pallets offline and transferring workpieces into the machine automatically, shops can operate more efficiently during shifts—or set up “lights out” unattended machining overnight without additional staffing.

Why Add a Multi-Pallet Pool to Your 5-Axis Machining Center?

-

Minimize spindle idle time

-

Increase machine utilization

-

Expand throughput without adding additional machines

-

Empower operators to manage more machines simultaneously

-

Enable continuous “lights-out” production

This directly reduces cost per cycle per part and helps manufacturers compete against low-labor-cost global markets without sacrificing quality or lead time.

Automatic Multi-Pallet Pool System Overview

19-Pallet Automatic Changer System

-

Holds nineteen (19) round 10" diameter aluminum pallets

-

Each pallet supports up to 75 lbs (34.5 kg)

-

Store and schedule 19 identical parts or 19 different jobs

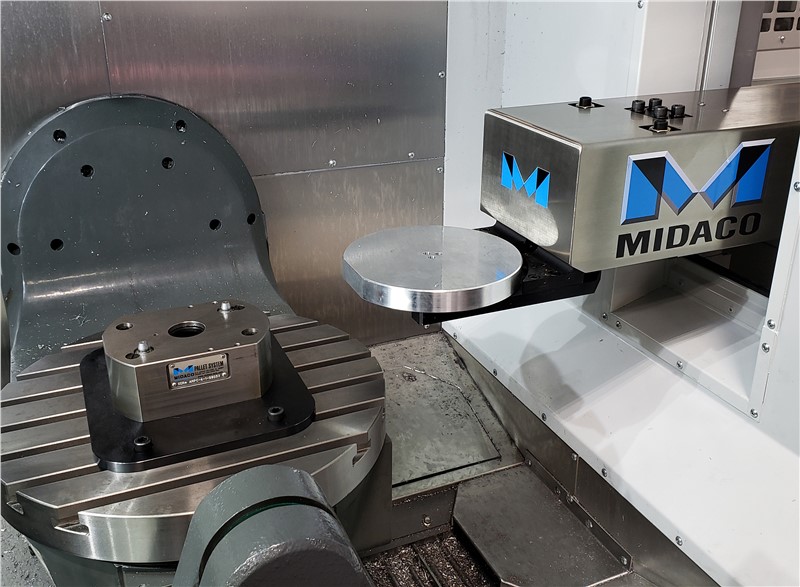

Seamless Pallet Transfer and Rotation

Unattended 5-Axis Machining

Schedule multiple production runs and allow the machine to:

-

Cut overnight

-

Run during breaks

-

Operate while operators manage other tasks or other machines

Key Performance Benefits

| Benefit | Result |

|---|---|

| “Lights-Out” 5-Axis Machining | Increased production capacity without labor cost |

| Reduce Machine Idle Time | Maximize ROI from new or already-installed machines |

| Offline Setup While Machining | Operator loads parts and fixtures while the spindle is cutting |

| Simplifies High-Mix, Low-Volume Production | Machine multiple jobs without stopping the mill |

| Precision Repeatability ±0.0001" | Ideal for complex tight-tolerance components |

| Expand System Scalability | Pallets can interchange between machine cells or departments |

Industry-Standard Safety & Global Compliance

The Result? Faster Output. Lower Cost Per Part. Higher Profitability.

By allowing operators to set up offline instead of tying up the spindle, manufacturers can dramatically increase utilization on both new and existing 5-axis machining centers. This means more throughput.— without adding shifts or expanding floor space.

Ready to Improve Your 5-Axis Productivity?

Let’s discuss your machining goals and determine the best pallet pool configuration for your production environment.

For more information

Call or complete our online contact form today