Go BIG or go small to increase productivity and decrease downtime on your CNC Equipment. MIDACO Pallet Changers adapt to ANY brand machining center.

Automatic Pallet Changers are servo driven and are designed to offer a fast pallet change time along with these additional benefits:

- Decrease in load time by switching parts outside

of the machine tool.

- No overhead obstructions for your crane access.

- Operator is not leaning into or climbing around

inside a machine tool to clamp and fixture parts on the VMC table.

- With multiple dedicated pallets you have additional set-ups available for your diverse machining needs.

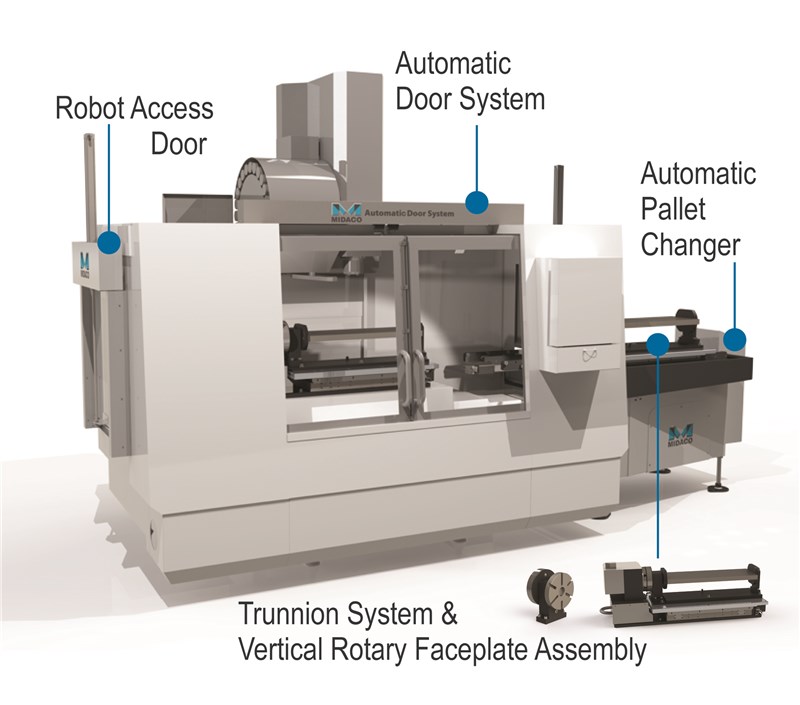

MIDACO offers a full line of Automation Solutions to fit your Machining Centers

- Manual Pallet Changer System

- Pallet sizes from 12.75"x 10.5" (234mm x 267mm) up to 60" x 25" (1524mm x 635mm)

- Up to 1,000 lb (454 kg) weight capacity (2000 lb optional upgrade)

- Automatic Pallet Changer System

- Pallet sizes from 22" x 14" (229mm x 356mm) up to 190" x 72" (4826mm x 1829mm)

- Up to 32,000 lb (14,528 kg) weight capacity (with weight evenly distributed).

- Automatic Multi-Pallet Changer System for 5-axis machining

- 19 stations each with a 10" (254mm) dia. round pallet

- Trunnion System for 4th Axis machining

- No Cable Management Needed

- Turn your Vertical into a Horizontal

- Automatic Door System

- For single and double doors

- Operator ergonomic benefits

- Ideal for robot loader applications

- Robot Arm (UR10) for Automatic Pallet Changer

- Automate Repetitive Part Set-Up Tasks

- For Automatic Pallet Changers up to Series A40SD

- Move Payloads up to 22 lbs (10 kgs)

- Flexible Reach of 51.2" (1300mm)

- Program Waypoints with Intuitive 3D Visualization

See MIDACO automation solutions in action at IMTS 2018, McCormick Place, Chicago. in the Metal Cutting Pavilion, South Hall booth #339347, September 10-15

Comments